LXZ6000 continuous frying line

This complete set of equipment is widely used, and can fry various foods such as potato chips, shrimp sticks, and rice noodles.

Equipment introduction

This complete set of equipment is widely used, and can fry various foods such as potato chips, shrimp sticks, and rice noodles. This complete set of equipment integrates the functions of frying, conveying, oil filtering and seasoning, and the control is accurate and reliable. The equipment is frying while conveying, with strong continuous production without interruption, which greatly improves production efficiency and saves a lot of human resources. Frying oil turnover rate is high. The pot body and the conveying can be separated freely, which is convenient for cleaning; the mesh belt conveys the feeding, and the feeding is uniform. It can be heated by various energy sources such as fuel oil, gas, and coal.

The complete set of frying equipment has reasonable design, high degree of automation, convenient operation, energy saving, small processing loss, and all controls are concentrated in the control cabinet.

Features:

1. The pot body and the conveying are separated design, which is convenient for cleaning the residual materials. The pot body uses limit switches to control its position during the lifting and lowering process. 2. The high-efficiency thermal oil boiler is used for circulating heating. The frying oil heats up rapidly and the oil temperature fluctuates little. During the frying process, the dynamic oil filter system is used to remove the waste residue at any time, keep the frying oil fresh, and comprehensively solve the frying caused by the residue of the oil residue. The problem of oil deterioration. Adjust the pressure of the hot oil circulation pump to ensure that the hot oil has a certain impact force when entering the fryer to prevent material accumulation and scorch.

3. Vibration-type oil filter, dusting, simple structure and complete functions; drum-type seasoning, so that the seasoning and the product are better mixed, and the seasoning effect is better.

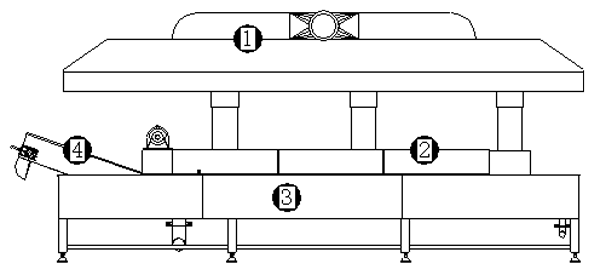

Schematic diagram of equipment structure

1. Fume hood 2. Feeding device 3. Fryer body 4. Conveying and lifting device

technical parameter:

Transmission drive power: 1.5kw

Increase drive power: 0.75kw

Circulating oil pump power: 5.5kw

Boiler required power: 400,000 kcal burner

Frying temperature: adjustable from 0 to 250°C

Production capacity: 800~1500㎏/h

Dimensions: 6500×1350×2800mm

Related Products

Related News

Submitted successfully

We will contact you as soon as possible