Double-drum flavoring line

This equipment is a small food automatic spraying seasoning processing equipment developed by our company based on years of experience in the food market. It can complete the multi-component automatic batching, spraying and seasoning processes of various multi-component puffed snacks and snack products.

EQUIPMENT INTRODUCTION

This equipment is a small food automatic spraying seasoning processing equipment developed by our company based on years of experience in the food market. It can complete the multi-component automatic batching, spraying and seasoning processes of various multi-component puffed snacks and snack products.

DEVICE APPLICATION

1. The ingredients of puffed snacks are mixed and sprayed for seasoning

Second, the sugar seasoning of peanuts and beans

3. Sugar hanging treatment before puffed food is formed

Fourth, other spraying, seasoning, sugar hanging process

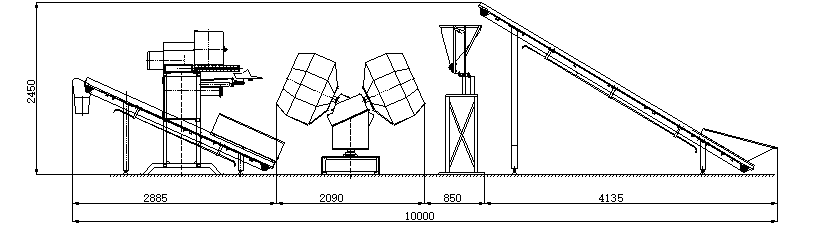

MAIN STRUCTURE

WORK PROCESS

The feed elevator starts to transport the material to the automatic weighing scale. When the set weight is reached, the feeding elevator stops working, the rotating octagonal cylinder receives the material in the automatic feeding scale, the base rotates 180 degrees to the second station, and the shotcrete truck on the side starts to spray; the set time is reached After that, the dusting truck starts to sprinkle dust. When the set time is reached, the cylinder of the octagonal base works to dump and discharge the material to the discharge conveyor; after the discharge is completed, the octagonal cylinder returns to its position, and the base rotates 180 degrees to the first station and starts to descend. One working cycle; when the octagonal cylinder receiving the material starts to work at the second station, the other octagonal cylinder receives the next batch of weighed materials at the first station, and the two octagonal cylinders work at the same time. . During the operation of the two-end octagonal cylinder seasoning machine, the octagonal cylinder keeps rotating.

TECHNICAL PARAMETERS (PLEASE REFER TO THE ACTUAL PARAMETERS FOR SPECIFIC PARAMETERS)

1) Feed elevator: 1 set

Power: 0.37kw

Belt material: food grade

Lifting height: 2.7 meters

2) Automatic feeding scale: 1 set

Silo volume: 0.6m2

Material: 304 stainless steel thickness 1.5mm

3) Octagonal cylinder with two ends: 1 set

Barrel volume: 89L

Barrel material: 304 stainless steel δ=2mm

Barrel speed: 30r/min

Barrel rotation power: 4x1.5kw

Base drive power: 0.75kw

Working cycle: about 2min

4) Slurry cylinder: 1 set

Tank volume: 200L

Heating power: 2kw

Stirring power: 0.37kw

Pulp power: 1.5kw

Dimensions: 1300×650x1155mm

5) Quantitative dusting and spraying truck: 1 set

Powder silo volume: 80L

Volume of batching hopper: 3L

Power: 0.75kw

Material: 304 stainless steel δ=1.5mm

Nozzle shape: fan

6) Discharge conveyor: 1 set

Power: 0.37kw

Belt material: food grade plastic

Conveyor belt width: 600mm

Related Products

Related News

Submitted successfully

We will contact you as soon as possible