YMP-II Roller Oven

This machine is a high-temperature baking equipment, and the working temperature can reach 350 °C.

Equipment overview:

This machine is a high-temperature baking equipment, and the working temperature can reach 350 °C. When working, the material first enters the lower hopper of No. 1, and then goes through the vibrating feeder of No. 2 into the screw conveying cylinder of No. 5. The inside of the screw conveying cylinder is heated by No. 7. The fan provides the heat source, and the heat is continuously circulated by the serial number 8 circulating fan to make the inside of the screw conveying cylinder reach 200-350 °C. The screw is used to drive the material to turn over and transmit, so that the material is baked evenly. This design makes the baking effect excellent.

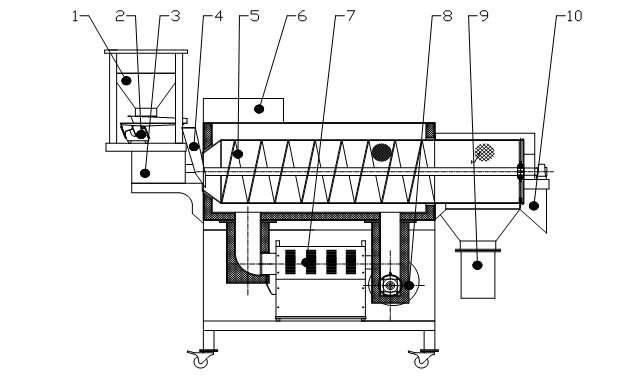

Schematic diagram of equipment

1. Feeding hopper 2. Vibrating feeder 3. Drive motor 4. Feeding port

5. Screw conveyor 6. Control cabinet 7. Hot air blower 8. Circulation blower

9. Waste hopper 10. Feeding port

The main technical parameters:

Production capacity: 80—120㎏/h

Total power: 31.128KW

Main drive power: 0.37 KW

Vibrating feeder power: 8W

Circulating fan drive power: 0.75KW

Heating power of hot air blower: 30KW

The maximum air volume of the hot air blower: 20m3/min

The maximum air temperature of the fan: 400 ℃

Number of hot air blowers: 1

Dimensions: 2500×1200×2000mm

Installation and commissioning:

Place the device in a ventilated and dry place. Choose a flat and solid ground and place it stably to prevent uneven force on each part of the body and affect the normal operation of the equipment.

The power supply should be equipped with a knife switch, and the equipment should have reliable grounding protection.

Turn on the power and check that the machine has no abnormality before it can be put into use.

Instructions

Before starting the machine, check whether the connecting parts are connected reliably, whether there is a virtual connection in the electrical wiring, and check whether the stirring cage is clean.

Check whether there are foreign objects in the hopper, open the vibrating feeder to check the amplitude, and the amplitude can be adjusted by the knob of the control box!

Turn on the main drive motor and check whether the motor is rotating forward. Note: the screw cylinder is in the counterclockwise direction! Adjust the speed to an appropriate range. The amount of feeding is accelerated according to the increase of temperature. Generally, the motor speed of corn flakes is 800-1000 rpm when the heating chamber is 240 °C, and the speed is 1000-1300 rpm when the heating chamber is 270 °C! The specific speed is adjusted according to the product requirements!

Set the temperature first. Generally, the corn flakes are set between 240°C and 280°C. When turning on the heating, first turn on the circulation fan switch, otherwise the heating wire will be burned out because no air enters the hot fan!

Before the material enters the screw conveying cavity, check that the moisture content of the material is not too wet. Usually, the moisture content of the material should be controlled below 8%, otherwise it will stick to the screw wall and form slag due to too much steam!

After the production is completed, first turn off the heating, but the circulating fan must not be turned off, it needs to run for more than half an hour, and then turn off when the temperature drops to 120 °C!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible