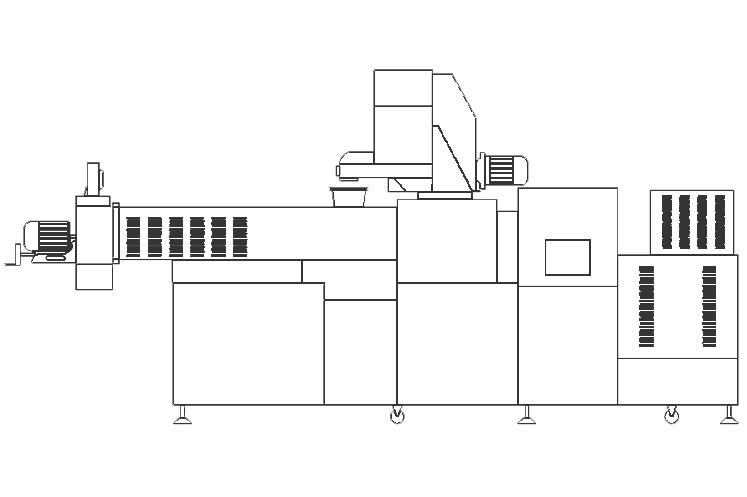

SLG65-DJ twin screw extruder

The SLG65-DJ twin-screw extruder adopts the international advanced twin-screw extrusion technology and combines our company's rich experience in puffed food technology research for many years.

This series of mainframes is suitable for a wide range of raw materials. It can be used corn, rice, millet, black rice, mung bean, buckwheat and other whole grains as raw materials. Puffed food and fast food porridge (paste) with various flavors processed by auxiliary technology.

This equipment is SLG65-D type upgrade equipment

The SLG65-DJ twin-screw extruder adopts the international advanced twin-screw extrusion technology and combines our company's rich experience in puffed food technology research for many years.

This series of mainframes is suitable for a wide range of raw materials. It can be used corn, rice, millet, black rice, mung bean, buckwheat and other whole grains as raw materials. Puffed food and fast food porridge (paste) with various flavors processed by auxiliary technology.

SLG65-DJ twin-screw extruder has reasonable design, high degree of automation, convenient operation, small footprint, energy saving, and small processing loss, which can be deeply redeveloped and applied to grains. The host adopts a stable and reliable frequency conversion speed regulation system. It belongs to the domestic advanced level. Its development and production fill the gap of domestic small-diameter twin-screw puffing equipment, and it has been recommended as a domestic high-quality food machinery by the China Packaging Food Machinery Association of the Ministry of Electrical and Mechanical Services.

Application field:

1. Leisure puffed food

Using corn, rice, millet, vegetables, seafood and other raw materials, it can produce various flavors and shapes. "Claas", Guaiguai Crisp, Baby Crisp, Cheerios and other market-manifolded full-puffed snacks.

2. Nutritious porridge

It can produce fast-food porridge (paste) products. The porridge (paste) products produced have good instant solubility, and can be drunk in warm water for 2 minutes. The main varieties are: breakfast, dinner porridge, student snack porridge, curative effect porridge, insurance porridge, baby porridge, elderly porridge, puffed oil tea, instant porridge, nutritional porridge, eight-treasure porridge, jade milk soup, black sesame paste and others with local flavor porridge (paste).

3. Soy protein, tissue protein, artificial meat

It can produce the popular soy tissue protein on the market. Soybean tissue protein is made of low-modified defatted soybean meal, soybean protein concentrate, colloid and modified starch through mixing, extrusion and puffing to make it textured, resulting in a structure similar to muscle and fiber characteristics. Compared with animal protein, it is cheap, cholesterol-free, and has good absorption. After rapid water absorption, the texture is very similar to that of animal protein. Because it is in a dry state after extrusion processing, the content of microorganisms is low, the shelf life is long (can be stored for about 1 year), and the tissue protein is easy to color and enhance flavor, and can be made into various foods.

4. Other applications

It can produce fillings, cake fillings and solid powder fillings for cold food products. Large cold food manufacturers can use equipment to produce fillings for ice cream and ice cream products, which can reduce the cost of the product, improve the grade of the product, increase the viscosity of the material liquid and improve the puffing rate of the product. The stability of thermal vibration is beneficial, and it can be used to process filling materials for pastry products, so that the product is stable, unique in taste and flavor, and saves energy; it can produce fillings for solid beverages; such as: peanut milk powder, soybean milk powder, etc. It can process raw materials for some liquor manufacturers and brewers, shorten saccharification time, shorten fermentation cycle, improve equipment utilization, and improve product efficiency.

Host structure

The machine consists of five parts: extrusion system, lubrication system, thrust mechanism, transmission system and heating system.

The main parts of the twin-screw extrusion system are the screw and the screw sleeve. The two screws are left-handed, mesh with each other, and rotate in the same direction. During the working process, the materials that stick to the screw are scraped and pushed forward. The screw is composed of 11 parts, and the pitches are 56mm, 48mm, 40mm, 36mm, 28mm and 24mm respectively. All threads are trapezoidal with a depth of 9.5mm. The pitch of the screw sleeve at the end of the screw is 24mm, and four semi-circular grooves are evenly distributed in the axial direction. When the material passes through, it can be fully affected by the shear force, increase the internal energy, and complete the expansion. The screw is connected by a keyway bushing. The whole concentric screw is formed, and this connection method has good interchangeability, convenient assembly and disassembly, and easy replacement.

The lubrication system is composed of a gear pump, an oil tank and an oil circuit, which force lubricating and cooling the rotating parts of the distribution box.

Technical parameter

l Screw diameter: 65 mm

l Screw length: 1500 mm

l Screw speed: 0~250 rpm

l Processing capacity: 100~150 kg/h

l Temperature control range: 0~399 ℃

l Motor power: 22KW (30KW for protein production)

l Machine center height: 1020 mm

l Dimensions: 3900×1050×1800(mm)

Related Products

Related News

Submitted successfully

We will contact you as soon as possible