High Yield Bread Crumb Production Line

1. As a food additive, the food wrapped in bread crumbs and then fried has a crispy taste and a beautiful golden appearance.

2. It can alleviate the time for food to be fried and burnt. When making fried foods, it is easy to fry and burn without paying attention. Adding bread crumbs can alleviate this phenomenon.

3. To create a unique taste for food, sprinkling a layer of bread crumbs when making desserts and cakes can increase the taste of the food, making the product rich and delicious in texture.

The product produced by the bread crumb production line is a widely used food additive, which is mainly used in the frying process of food, such as Chicken-fried steak, fried chicken steak, fried chicken leg, etc. The food made by adding bread crumbs and frying it has a crispy taste, rich layers, and is deeply loved by consumers. The bread crumb production line developed by our company has changed the traditional production process of bread crumbs. From fabric input to crushing and forming, it is produced on an assembly line, requiring fewer personnel, reusable surplus materials, no waste, and reducing production and manufacturing costs.

Our company's bread crumb production line has multiple configurations to choose from, and customers can customize their choices based on their production needs. In this production line, the extrusion and expansion host is the core part. The following is an introduction to the multiple configurations of extrusion and expansion hosts in this production line:

| Model | Installed power | Power consumption | Capacity | Dimension |

| SLG65-C | 55.36kw | 36kw | 100-150kg/h | 30400*2000*2200mm |

| SLG70-A | 95.76kw | 62.24kw | 250-300kg/h | 32500*2000*2600mm |

| SLG85-A | 140.76kw | 106kw | 350-400kg/h | 33000*3000*3000mm |

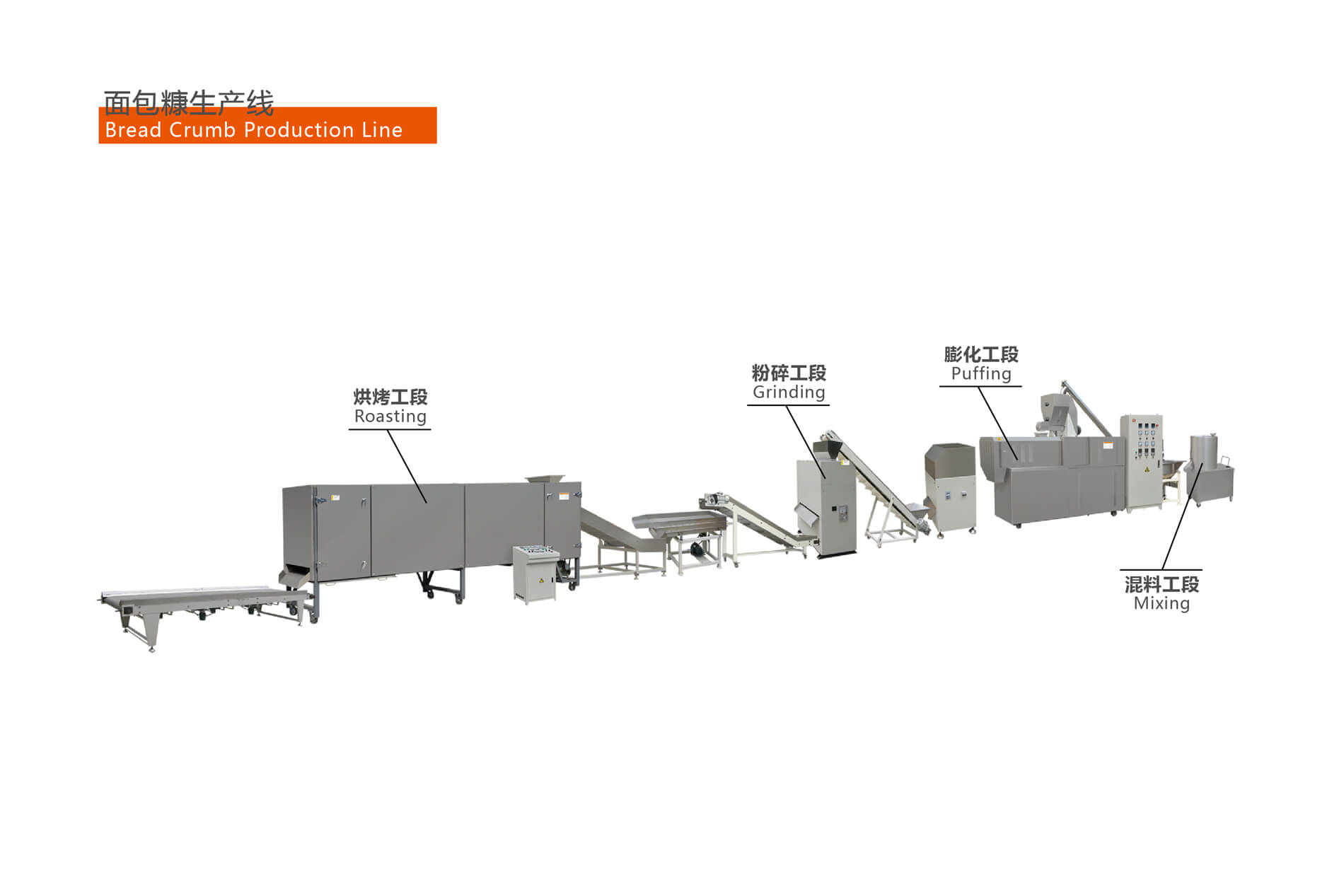

The following is an introduction to the process flow of the production line, the bread crumb production line developed by our company has high automation, high production efficiency, and good product quality, making it the best choice for investment in production.

1. Mixer: Mix the necessary raw materials for production evenly here.

2. Spiral feeding machine: The mixed raw materials are transported to the extrusion and puffing machine, and the raw materials can be stirred twice using spiral rods, making the feeding more uniform and stable, and less prone to scattering.

3. Twin screw host: The mixed raw materials are extruded and expanded in the equipment, and the raw materials pass through the equipment, ultimately extruding the semi-finished products through the extruder.

4. Bread bran cutting machine: Cut the semi-finished products extruded by the extruder.

5. Large elevator: Transport the cut product to the next device.

6. Pulverizer: Crushes the conveyed bread crumbs to produce crumbs in the form of crumbs, needles, and other shapes.

7. Z-conveyor: Conveys the product to the next device inside.

8. Bran screening machine: Screen the crushed products, retrieve and crush the products that do not meet the standards, and reuse them again.

9. Large elevator: The selected high-quality products are fed into the oven, and the height of the elevator can be freely adjusted according to the height of the oven.

10. Triple layer electric oven: Adopting a multi-layer oven, suitable oven capacity can be selected based on production capacity. The equipment is evenly baked and easy to control temperature.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible