Introduction To Fully Automatic Bread Crumb Production Line

1. The production process includes feeding, mixing, puffing, cooling, crushing, etc. Compared to traditional baking methods for producing bread bran, puffing technology has advantages such as high yield, continuous production, energy conservation, and labor saving;

2. The difference in taste and quality of the products is minimal, greatly replacing the traditional bread bran production process and enriching the product category. It is no longer limited to the appearance of crumbs, and the selection of raw materials is also more diverse;

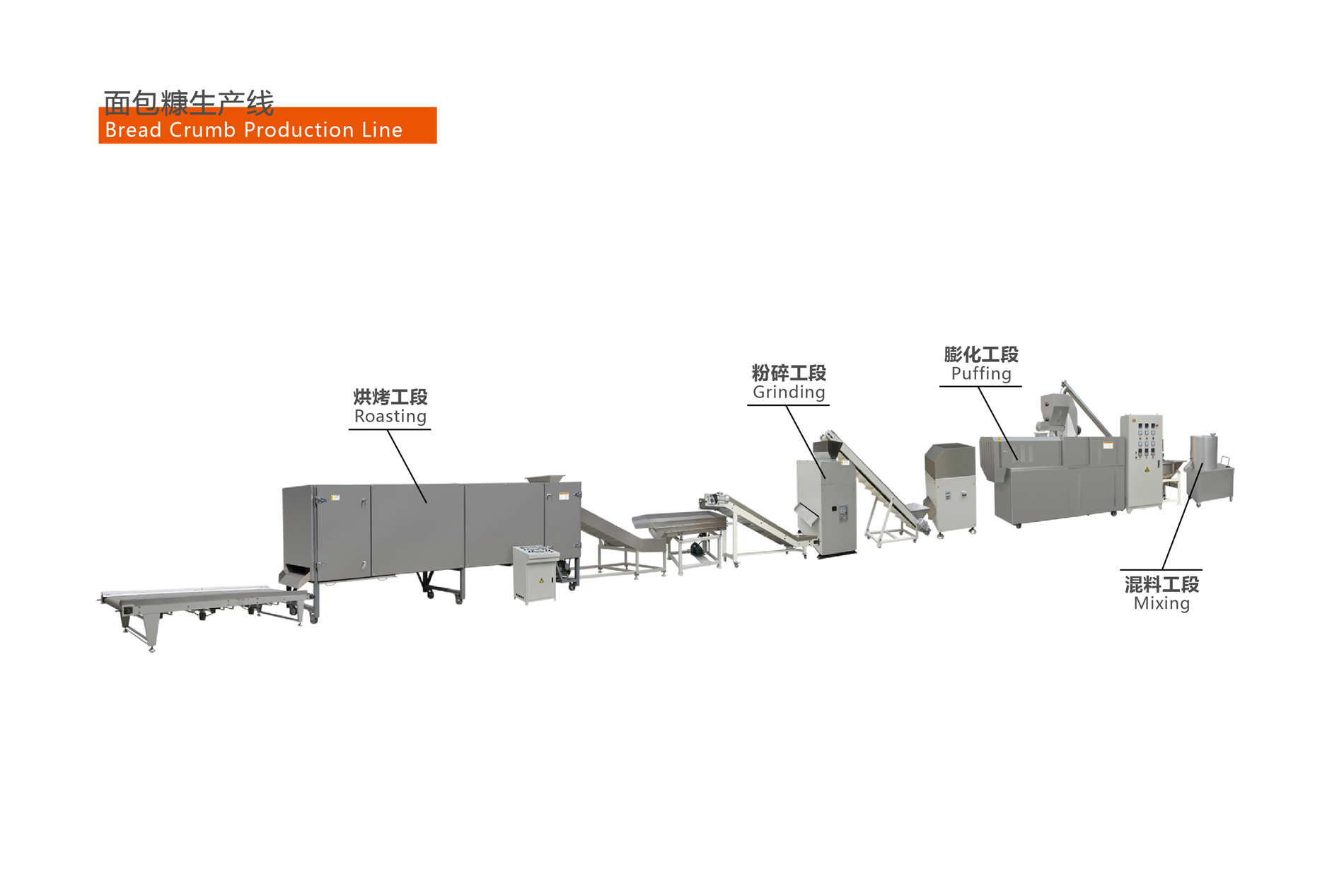

The bread crumb production line developed by our company adopts a twin-screw extrusion puffing process, which converts flour or other powdered grain raw materials into crumbs, needle shaped or flake shaped bread crumbs and snowflake flakes. The production process includes feeding, mixing, puffing, cooling, crushing, etc. Compared to traditional baking methods for producing bread bran, the use of puffing technology has advantages such as high yield, high continuous production capacity, energy conservation, and labor saving. Moreover, the difference in taste and quality of the products is minimal, greatly replacing the traditional bread bran production process and enriching the product category. It is no longer limited to the appearance of crumbs, and the selection of raw materials is also more diverse.

Introduction to the process flow of bread crumb production line:

1. Mixer: Mix the raw materials required for production with a certain amount of water evenly. This production line mainly uses flour, corn flour, etc. as the main raw materials,

2. Spiral feeding machine: The mixed raw materials are transported to the feeding hopper of the extruder, and the use of spiral rod feeding can ensure uniform and stable feeding without easy scattering. The spiral rod can also perform secondary mixing on the raw materials to make them more uniform.

3. Twin screw host: The mixed raw materials are extruded and expanded here, changing the original molecular structure of the raw materials, causing them to expand, and finally being extruded and formed by an extruder.

4. Bread bran cutting machine: Cut the semi-finished products extruded by the extruder into products of the same size.

5. Large elevator: Transport the cut product to the next equipment.

6. Powder and bran machine: Crush the semi-finished products transported and make them into powder and debris like products of the same size.

7. Z-conveyor: Conveys the product to the next device.

8. Bran screening machine: Screen the crushed and formed products, select unqualified products, and reuse them after crushing, saving raw materials and ensuring product quality.

9. Large elevator: Transport the screened products to the oven, and the height of the elevator can be freely adjusted according to the height of the oven.

10. Three layer electric oven: Dry the product to reduce internal moisture, making it crispy and easy to store.

11. Cooling conveyor: The baked product is cooled here and transported for packaging.

The bread crumb production line produced by our company has multiple configurations and yields, and customers can choose the appropriate production line configuration based on factors such as yield. The following is an introduction to the main parameters of several extruders on this production line:

| Model | Installed power | Power consumption | Capacity | Dimension |

| SLG65-C | 55.36kw | 36kw | 100-150kg/h | 30400*2000*2200mm |

| SLG70-A | 95.76kw | 62.24kw | 250-300kg/h | 32500*2000*2600mm |

| SLG85-A | 140.76kw | 106kw | 350-400kg/h | 33000*3000*3000mm |

Related Products

Related News

Submitted successfully

We will contact you as soon as possible