Fully Automatic Fried Snack Production Line

1. Wide range of raw materials: raw materials can be corn flour, wheat flour, corn starch or their mixture.

2. Flexible operation: Fully automated production, products of different shapes can be produced by changing molds and auxiliary equipment.

3. Rich configuration: This production line is equipped with various extruders with different yields, and customers can choose the equipment that suits them according to their production needs.

4. Wide market: This product is loved by consumers around the world for its rich taste, crispy and delicious taste, and easy digestion.

The fried snack production line takes wheat flour as the main raw material, and can also be a mixture of corn flour, wheat flour and Rice noodles. By changing the mold and auxiliary equipment, various products can be produced. Such as salad fries, wave slices, salad slices, crispy rice dumplings, etc. The products produced have a crispy and non greasy taste, are rich in nutrients, easy to digest, and are loved by consumers around the world.

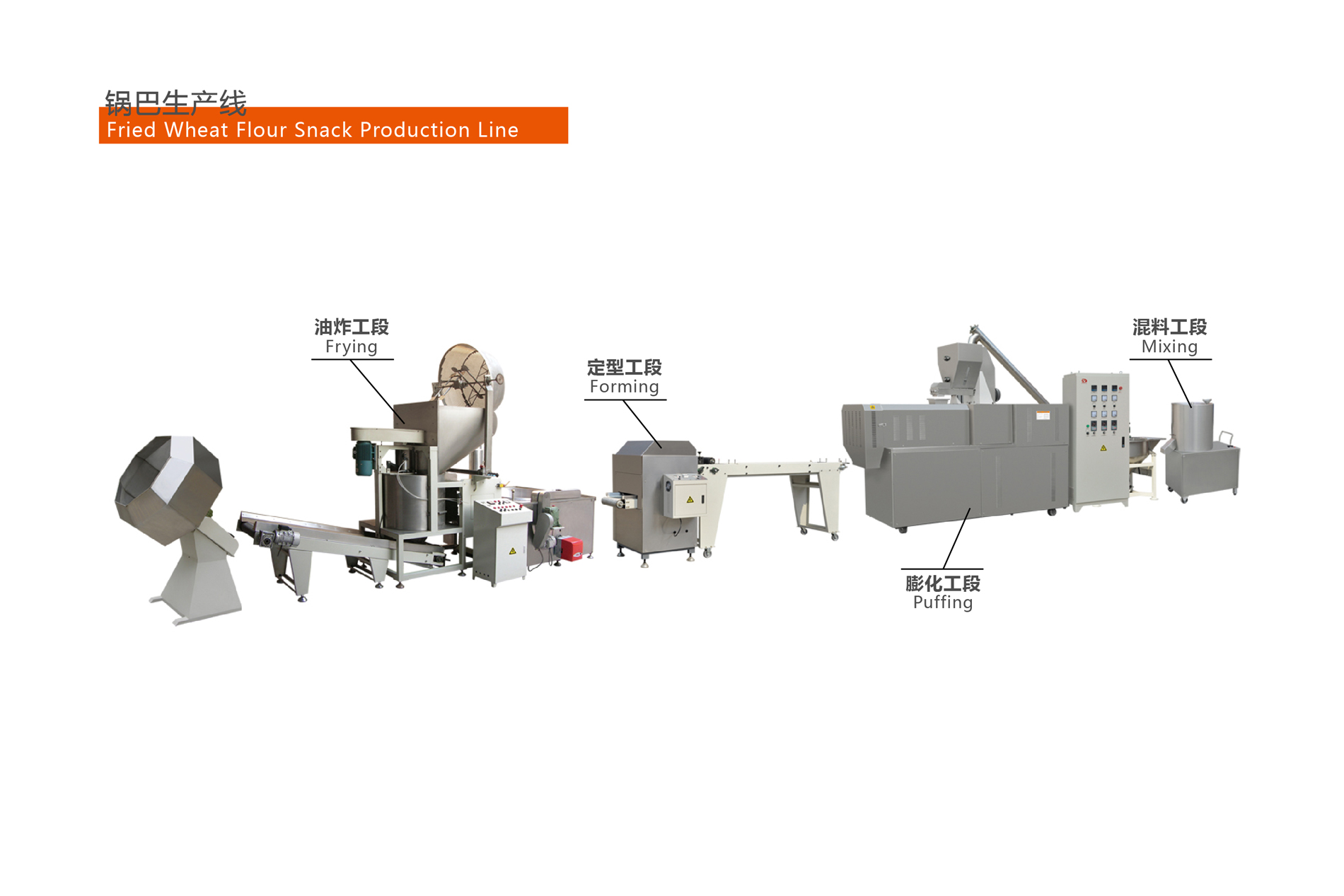

Our company's fried snack production line has multiple configurations and can customize different production equipment according to customer needs. The equipment types of this production line are diverse and suitable for different types of enterprises. The following is an introduction to the main process flow of the production line:

1. Mixer: Mix the raw materials and a certain amount of water required for production thoroughly and evenly to form the necessary materials for production.

2. Spiral feeder: The mixed raw materials are transported to the feeding hopper of the extruder, and the use of spiral rod feeding can ensure uniform and stable feeding without easy scattering. The spiral rod also has the function of secondary stirring.

3. Twin screw host: The mixed production materials are extruded and expanded, and the materials are subjected to high-temperature and high-pressure extrusion and kneading in the extruder, and finally extruded and formed by the extruder.

4. Traction cutting machine: Pulling and cutting semi-finished products into products of the same size and shape.

5. Automatic fryer: Fry the cut product to make it crispy in taste. Automatic fryers are easy to control temperature, highly automated, and evenly fried.

6. Octagonal seasoning machine: The fried product is seasoned, and the flavor can be determined according to production needs. Our company also has various seasoning equipment configurations.

Our company not only produces fried snack production lines, but also various types of puffed food production lines and various types of food production lines. During the cooperation process, we will provide you with high-quality services and various problem-solving solutions to ensure that you can purchase our equipment with confidence.

1. Pre sales, in sales, and after-sales consulting services;

2. Project planning and design services;

3. Debug the equipment until it functions properly;

4. Manage long-distance transportation of equipment from the seller's factory to the buyer's designated location;

5. Training on equipment maintenance and hands-on operation;

6.) New production technologies and formulas;

7. Provide a one-year full warranty and lifetime maintenance service.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible