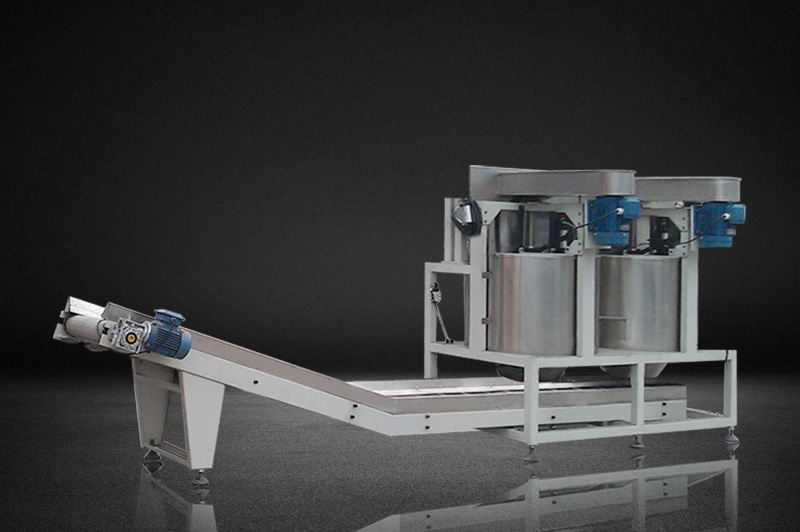

SYX-II double-tank de-oil line

The equipment is reasonable in design, easy to operate, and low in price. It is also equipped with a chassis for placing the receiving box and discharging conveying. The motor is equipped with a braking device, which greatly improves the work efficiency.

Overview:

The equipment is reasonable in design, easy to operate, and low in price. It is also equipped with a chassis for placing the receiving box and discharging conveying. The motor is equipped with a braking device, which greatly improves the work efficiency.

This machine is suitable for a wide range of raw materials, and can deoil food of various shapes.

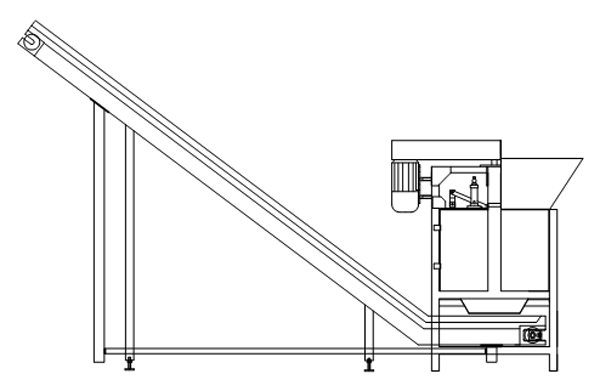

Device structure diagram:

The main technical parameters:

Driving power: 2.2KW

Diameter of oil drum: φ740㎜

Dimensions: 3500×2500×1850㎜

Weight: 220㎏

Main technical parameters of discharge conveying

Driving power: 0.55KW

Dimensions: 4120×700×2460㎜

Weight: 100㎏

Installation Notes:

1. According to the position of the production line, place the equipment on a flat and solid ground.

2. Fix the feet and place them stably to prevent uneven force on each part of the body and affect the normal operation of the equipment.

The power supply should be equipped with a knife switch, and the equipment should have reliable grounding protection.

Instructions:

1. Before starting the machine, check whether the connection parts are reliable and whether there is any virtual connection in the electrical wiring. Clean the outer barrel and the oil dumping barrel. The bottom oil return pipe port is well connected with the oil receiving device, and the material receiving box is placed at the bottom discharge port. below, and then put the discharge conveying.

2. Put the material that needs to be deoiled into the oil drum, turn on the drive motor, and carry out deoiling treatment.

3. After deoiling is completed, turn off the drive motor and wait for the equipment to stop running. Press the manual handle to raise the stopper cone, and the material enters the receiving box, so that the material can be conveyed better.

4. After the work is finished, the two windows of the outer barrel can be unplugged, and the outer barrel can be brushed.

maintenance:

1 Regularly check whether the fixing bolts of each connecting flange, bearing seat, and transmission system are loose, and if so, tighten them.

2 When it is not in use, the outer barrel and the oil dumping barrel should be cleaned to keep it clean.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible