Process Flow Of Doritos Production Line

1. The Doritos produced by the Doritos production line is a Corn flakes made from corn. Compared with other potato chips, it is crispy and chewy.

2. Doritos is a kind of fragile food. It tastes crisp and smooth, and has a strong grain flavor.

3. The equipment of Doritos production line is characterized by many optional models, flexible equipment configuration, a wide range of raw materials, a wide range of products and simple operation.

The Doritos production line developed by our company is mainly made of corn flour, Corn starch, big Rice noodles, wheat flour and other raw materials, which are extruded, rolled into triangular, round, square and other shapes of thin slices, and then baked for seasoning. Its crispy and non greasy taste is deeply loved by domestic and foreign consumers. The produced crushed materials can also be reused, greatly reducing production costs.

Technical parameters of each host of Doritos production line:

| Model | Installed power | Power consumption | Capacity | Dimension |

| SLG65-C | 54.33kw | 41kw | 100-150kg/h | 26400*4900*2000mm |

| SLG70-A | 77.33kw | 58kw | 200-250kg/h | 28200*4900*2600mm |

| SLG85-A | 122.33kw | 92kw | 350-400kg/h | 29000*4900*3000mm |

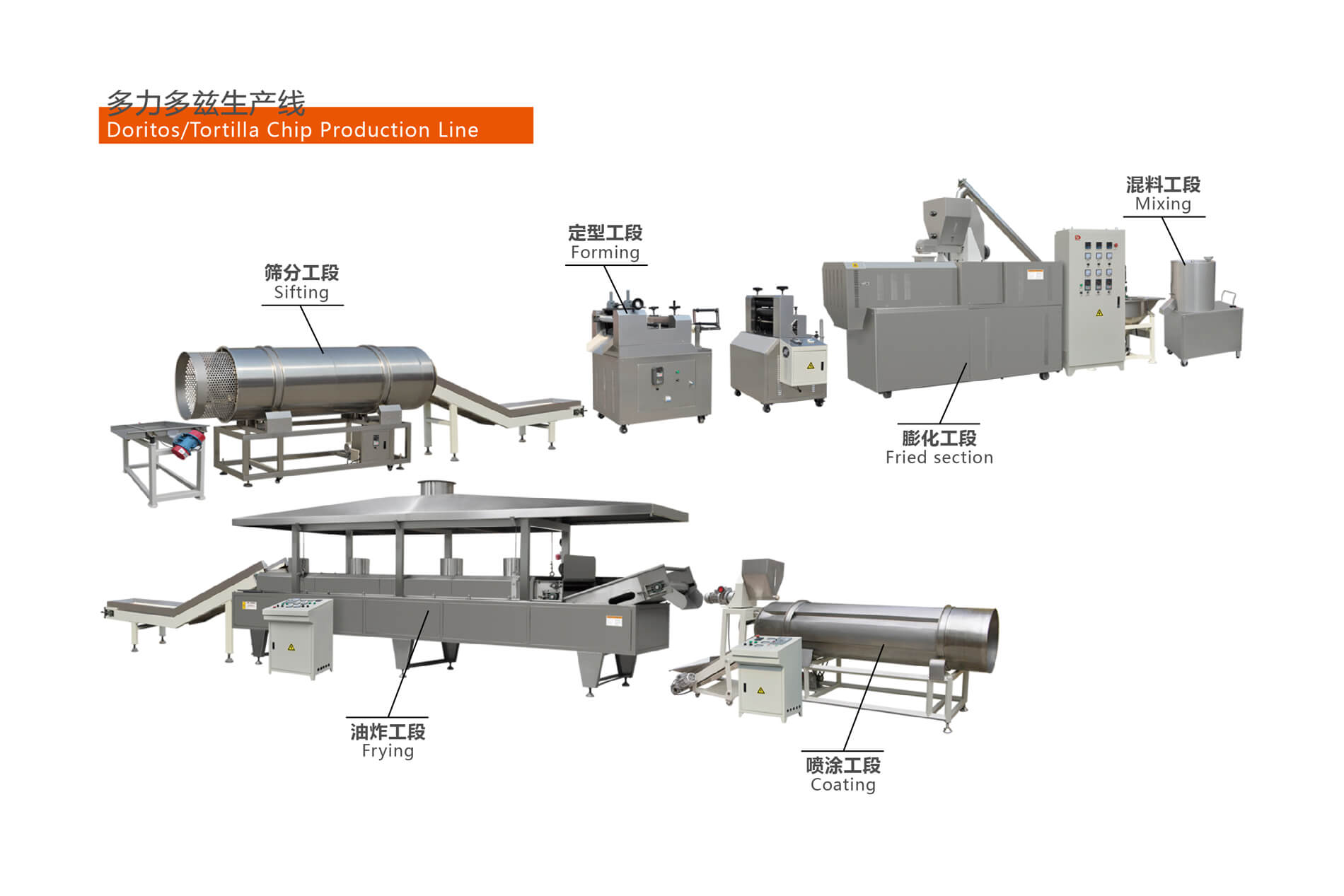

Process composition of Doritos production line equipment:

1. Mixing machine: Different models of mixing machines are selected based on the production line's output, and the mixing machine can mix the raw materials evenly here.

2. Spiral feeding machine: Utilizing spiral stirring conveyor to ensure uniform secondary mixing and convenient and fast feeding.

3. Twin screw extruder: different models of extruder are selected according to the different production lines, with the output of 100kg/h -400kg/h. The raw materials can be corn flour, Rice noodles, wheat flour, barley flour and other cereals, and the raw materials can be expanded here.

4. Traction cutting machine: Cut and shape the products produced by the expansion extruder to produce products of the same size and shape.

5. Rotary separator: The produced product is separated from the unqualified broken materials through the separator to ensure the high quality of the product, and the broken materials can be reused.

6. Elevator: Transport semi-finished products to the fryer, and the height of the air blower or elevator is determined based on the height of the fryer.

7. Vibration oil removal screen: Remove unqualified crushed materials and excess grease.

8. Seasoning line: There are various seasoning equipment such as octagonal drum, drum, lifting single drum, double drum seasoning line, etc., which can be configured according to production volume and product properties.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible