High Yield Fried Wheat Flour Snack Production Line

1. In terms of technology: the use of twin screw extrusion technology to replace the traditional cooking style pot production technology.

2. In terms of operation: The Guoba food production line integrates mixing, steaming, ripening, puffing, and shaping, without the need for a boiler. The production process is simplified, efficient, and environmentally friendly

3. Application: The raw materials of the fried rice noodle food production line can be either single materials such as big Rice noodles, corn flour, flour, or a mixture of them

4. Product aspect: Changing the mold can change the shape, and the fried and puffed food produced has a crispy taste without being greasy.

5. Production Products: Rice Guoba, Corn Guoba, Bean Flavored Guoba, Flour Guoba, French Fries, Potato Chips, Sharp Cornered Crisps, Vegetable Rolls, Pony Crisps, and other products

The fried wheat flour snack production line is a new technology that replaces traditional cooking Guoba production with twin screw extrusion technology. This production line is a high-quality production line that has been successfully developed and innovated by the company's scientific and technological personnel. It integrates raw material mixing, steaming, ripening, puffing, forming, frying, and seasoning. The production process is simplified, efficient, and environmentally friendly. There are a wide range of raw materials, such as large Rice noodles, corn flour, flour and other single materials, or mixed materials. The product form can also be changed by changing molds and auxiliary equipment, with strong flexibility. The produced products have a crispy and non greasy taste, and are loved by consumers of all ages.

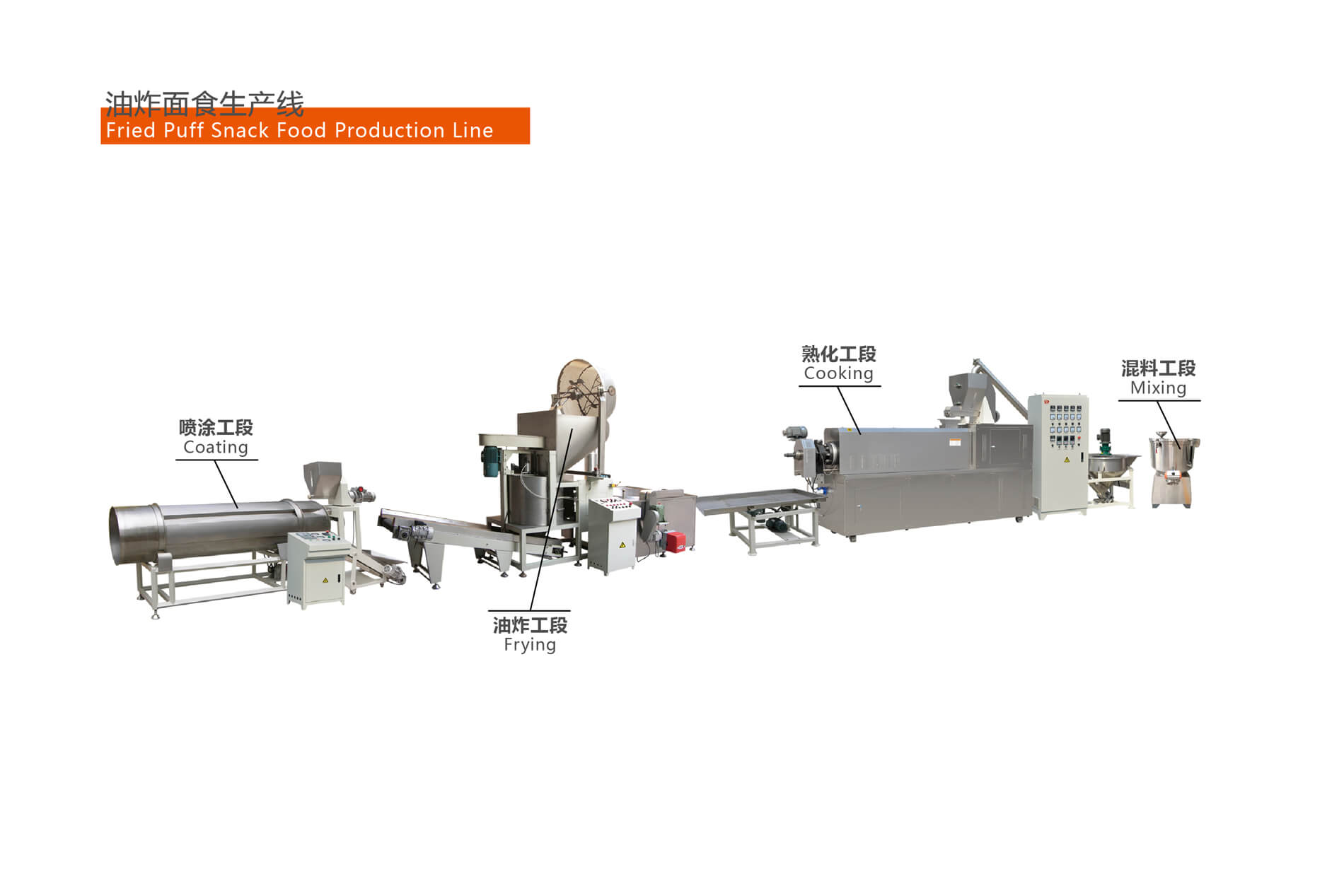

The fried wheat flour snack production line has multiple host configurations, and enterprises can choose different configurations of production lines based on their own production needs. The main process flow and equipment function of the production line: raw material stirring - feeding - extrusion expansion - cutting and shaping - frying - seasoning

1. Mixer: Mix and prepare the required raw materials and a certain amount of water evenly here

2. Spiral extractor: Conveys the mixed raw materials into the extrusion and puffing machine, and using spiral feeding can ensure uniform and stable feeding, not easy to spill, and efficient efficiency

3. Twin screw host: It is the core part of the entire production line and mainly comes in three models. The incoming raw materials can be extruded and expanded into the desired shape, and then extruded through an extruder

4. Traction cutting machine: Cut the products produced by the extruder into specified shapes

5. Automatic fryer: The cut product is fed into the fryer for frying, and the fried product has a crispy and delicious taste

6. Octagonal seasoning machine: The fried products are seasoned here, and the flavor of the seasoning can be determined according to production needs. The seasoning equipment can also be selected according to different production volumes, such as Octagonal seasoning machine, seasoning line, double barrel seasoning line, etc

Three main machine technical parameters for the fried wheat flour snack production line:

| Model | Installed Power | Power Consumption | Capacity | Dimension |

| SLG65-C | 40.75kw | 26kw | 100-150kg/h | 16500*2250*2900mm |

| SLG70-A | 76.05kw | 54kw | 250-300kg/h | 20000*2250*2800mm |

| SLG85-A | 121.05kw | 91kw | 350-400kg/h | 20800*3000*3000mm |

Related Products

Related News

Submitted successfully

We will contact you as soon as possible