Breakfast cereal production line customization and configuration

The first breakfast cereal was oatmeal, which was cooked, pressed, and baked. Developed countries in Europe and America began to use extrusion technology to produce breakfast cereals in the 1970s, and it has been rapidly developed and updated. At present, there are many kinds of breakfast cereal processing technology, such as: tablet cooking processing technology, cereal crushing cooking processing technology, extrusion processing technology and microwave vacuum expanding processing technology.

Extrusion process corn chips/breakfast cereal production line: With corn, wheat, oatmeal and other multiple grains as raw materials, after high quality twin-screw extruder curing molding, crisp products, high nutritional value, suitable for people of all ages.

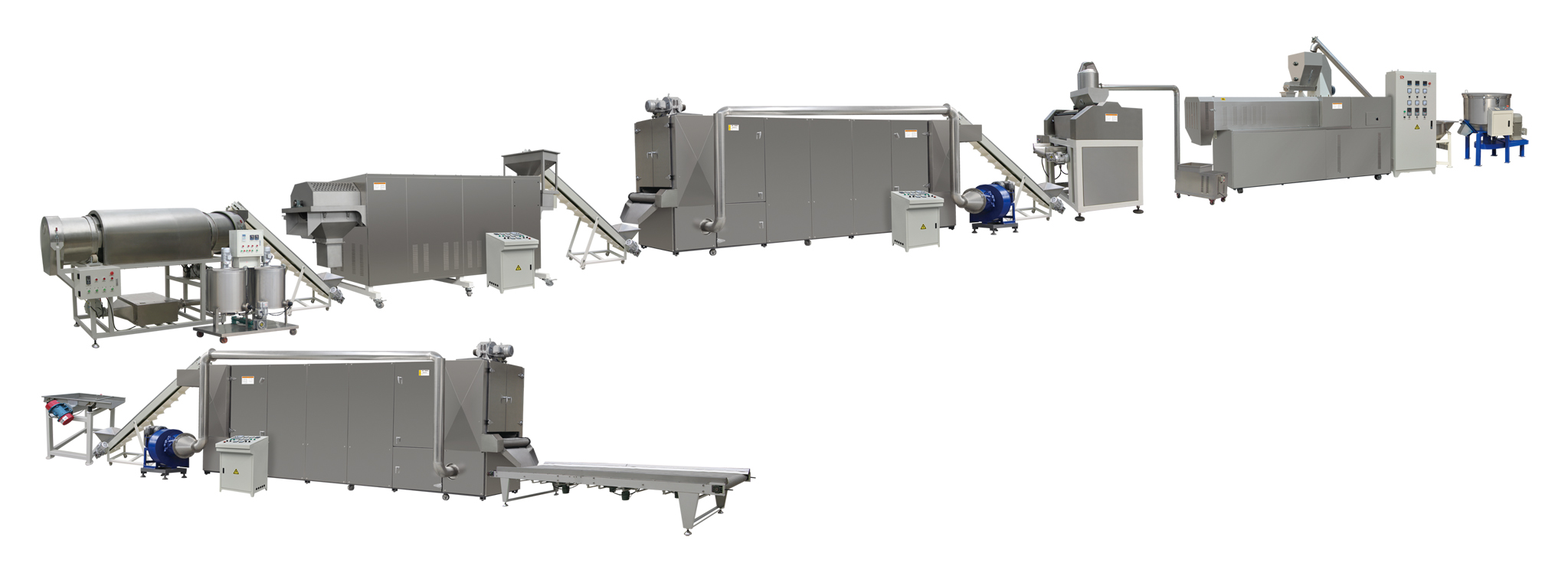

Equipment configuration

Powder mixer → screw conveyor → twin-screw extruder → Vibrating cooling machine → Air feeder 1→ Tablet press → Air feeder 2→ Pre-dryer → Hoist → Vibrating feeder → Air feeder 3→ Sugar sprayer → oven → cooling machine

Jinan DAYI Machinery Technology Co., Ltd. is located in the beautiful city of Jinan. The company has been engaged in the research and development of food production line machinery and production technology for a long time, the company's standard production technology, the operation concept of automatic control, and the focus on the development of stable and reliable production equipment. The company's designers have long-term experience in design, development, debugging and production, and have responsible on-site engineering personnel engaged in production and debugging work, and can provide you with standardized design, production, and debugging processes.