Learn About Automatic Bone Broth Production Line

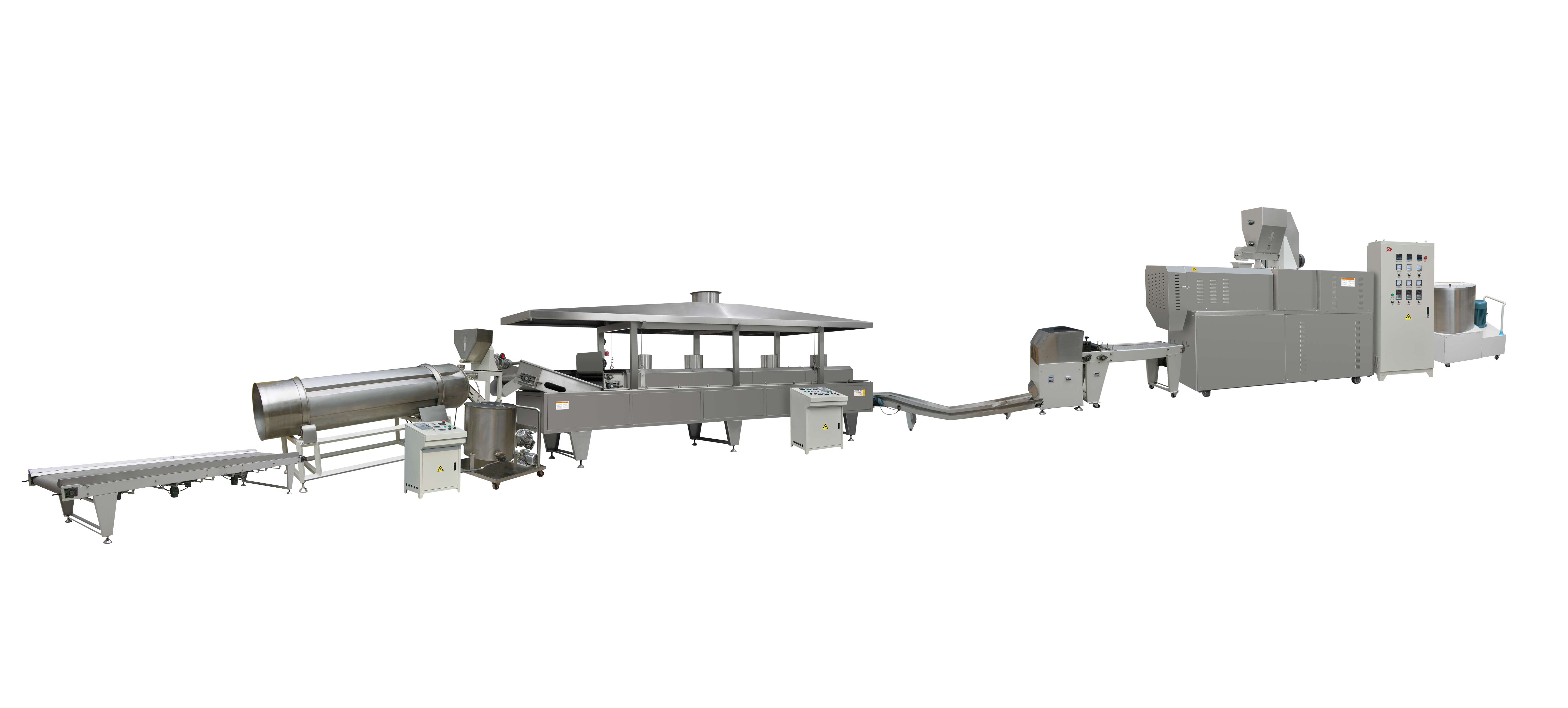

How to gradually transform from a traditional food enterprise that is mainly manual and auxiliary equipment processing to an automated manufacturing enterprise? Feeding, crushing, cooking, oil-water separation, filling... The fully automatic bone broth production line realizes the automatic process of large bone extract production. Using the original factory building, newly purchased equipment that has reached the domestic advanced level and a high level of automation, automatic circuit sanitation processing equipment (CIP system), automatic packaging machine, etc., to automatically upgrade the original large bone extract production process. Retrofit. After the big bone is fed and crushed, it will enter the 5-ton cooking pot through the pipeline. After being cooked at 90 degrees for 24 hours, it will be prepared. After the oil and water are separated, it will enter the automatic filling machine through the pipeline. After the production is completed, it must pass through the CIP hot water system. Automatic cleaning and disinfection. The entire production process of Dagu Dagu extract production has been automated.

Through automation transformation and upgrading, the production efficiency can be increased by more than 25%, the production human resources can be reduced by 20%, the automatic data collection rate can reach 30%, the factory automatic control input rate can reach 50%, the product quality stability can be improved, and safe production can be effectively guaranteed. In the next step, the company will increase the digitalization process on the basis of automatic production, so that production will enter a new era of intelligent and flexible production, and meet the needs of customers in the future for small batches, multiple batches, and individualization.