What is the performance of food drying equipment

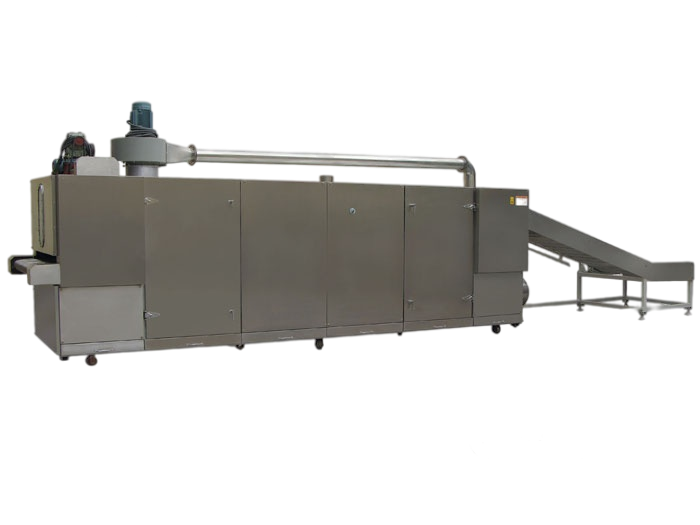

Food dryer has many uses. It is a commonly used continuous drying equipment, which can be widely used in chemical, food, medicine, building materials, electronics and other industries, especially suitable for sheets, strips, granular materials, The filter cake paste material can also be dried by a granulator or an extrusion molding mechanism.

This dryer, also known as mesh belt dryer, distributes the processed materials through appropriate mechanisms, such as star type, box swing type, mill or granulator, on the conveyor belt, and the conveyor belt passes through a Or channels of several heating units, each heating unit is equipped with an air heating and circulation system, and each channel has one or more dehumidification systems, when the conveyor belt passes, the hot air passes through the material on the conveyor belt from top to bottom Or from bottom to top so that the material dries evenly.

The large food dryer is a special equipment developed on the basis of the traditional mesh belt dryer. It has the characteristics of strong pertinence, strong practicability and high energy efficiency. It is widely used in the dehydration and drying of various regional and seasonal vegetables and fruits. According to the characteristics of product drying requirements, user process requirements, combined with decades of accumulated experience, we design the most suitable and high-quality vegetable drying equipment for users. Let's take a look at the performance characteristics of large food dryers:

Equipment structure:

The food dryer is composed of a horizontal cylinder, an exhaust pipe, a feeding device, a discharging device, a spiral device in the cylinder, a cleaning device, a material plate, an air guide device, a transmission device, a dust removal device and an electronic control device.

Large food dryer is a special equipment developed on the basis of traditional mesh belt dryer

Performance characteristics:

1. Solve the problem of water vapor returning to the material during the downstream dehumidification process of the traditional food dryer because the movement direction is consistent with the temperature direction of the system;

2. During the drying process, the hot air flows forward from the tail and fully contacts the material, and is fully utilized through heat conduction, convection and radiation heat transfer;

3. The heat energy is directly transferred to the material, so the water of the material is continuously evaporated in the body of the food dryer cylinder, and the air inlet device will bring a lot of water and humid airflow to prevent secondary pollution caused by dust discharge.