High Quality Fully Automatic Nutritional Powder Production Line

1. The instantaneous high temperature, high pressure, and expansion effect during the extrusion process can not only change the structural characteristics of the material, promote starch gelatinization, instantly reduce pressure, and cause changes in the structure of the coarse grain organization, solve problems such as poor taste and digestion difficulty of the coarse grain, but also better retain nutritional components, sterilize and sterilize.

2. Compared with the raw material coarse grain powder, extrusion and expansion treatment enhances the thermal stability of coarse grain powder, weakens the shear thinning degree of the paste, makes it less prone to aging and retrogradation, and improves the freeze-thaw stability. Moreover, extrusion and expansion treatment makes the structure of coarse grain powder delicate and porous, thereby achieving the effect of rapid rehydration.

The nutritional powder production line developed by our company is another new extension of the twin screw extrusion technology. The traditional manual frying method for nutritional powder is inefficient, and hygiene and quality issues are difficult to control, resulting in a single processing material. Twin screw extrusion technology makes up for the above shortcomings. It can process a wide range of raw materials, including Rice noodles, corn flour, soybean flour, buckwheat flour, etc. At the same time, the production line can also strengthen various nutrients and produce multifunctional nutritional health food, such as red bean barley Rice noodles, buckwheat flour, black sesame paste, soybean flour, Rice noodles, etc.

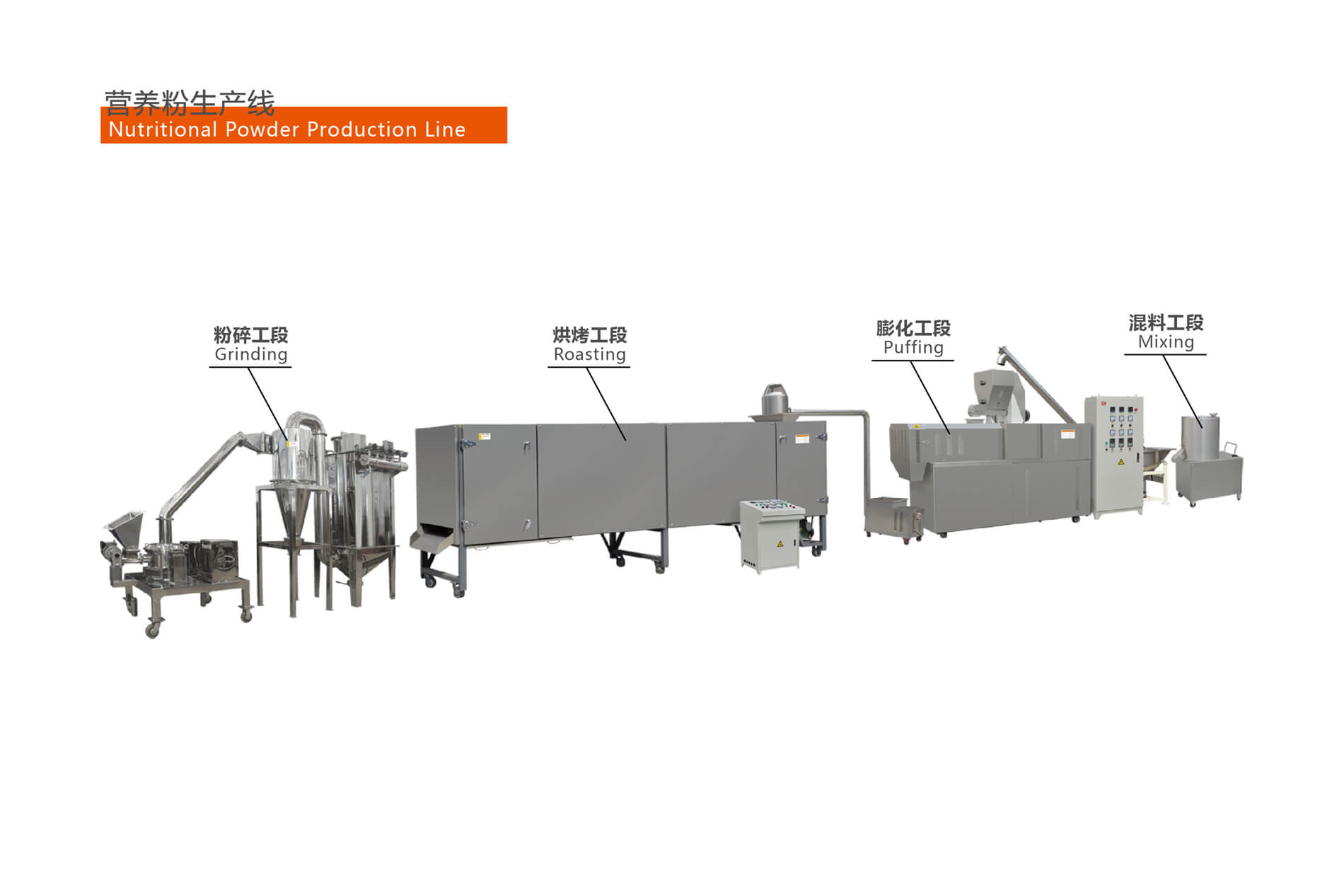

Process flow of nutritional powder production line:

1. Mixer: This equipment can fully and evenly mix the raw materials and a certain amount of water required for production here.

2. Spiral extractor: The mixed raw materials are transported to the extruder, and the use of spiral rod feeding can ensure uniform and stable feeding. The spiral rod also has the function of secondary stirring.

3. Twin screw host: Expands the incoming raw materials, changes the internal structure of the product, and extrudes them into shape.

4. Air blower: Conveys the products produced by the extruder into an oven, and the height of the air blower can be freely adjusted according to the height of the oven.

5. Multi layer oven: To dry the product and reduce internal moisture, our company has multiple models of ovens to choose from.

6. Ultramicro crusher: Crush the dried semi-finished products into powder form.

Technical parameters of each host in the nutritional powder production line:

| Model | Installed power | Power consumption | Capacity | Dimension |

| SLG65-CJ | 81.57kw | 53kw | 100-160kg/h | 16500*1150*2350mm |

| SLG70-A | 84.16kw | 55kw | 200-300kg/h | 17500*1150*2350mm |

Related Products

Related News

Submitted successfully

We will contact you as soon as possible