High Quality Nutritional Powder Production Line

The products produced by this production line are easier to digest and absorb, and are suitable for consumers of all ages.

This production line has multiple configurations and strong diversity, suitable for large, medium, and small enterprises.

High degree of equipment automation, high production efficiency, and high product quality.

Multiple nutrients can be selectively added to the product during the raw material configuration stage, resulting in a more nutritious product.

The nutritional powder production line developed by our company is a new extension and application of twin-screw extrusion technology. The traditional manual frying method for nutritional powder has low efficiency, hygiene, and quality issues that are difficult to control, resulting in a single processing material. Twin screw extrusion technology makes up for the above shortcomings. It can process a wide range of raw materials, including Rice noodles, corn flour, soybean flour, buckwheat, oats, etc. This production line can also add various nutrients such as vitamins, proteins, etc. when mixing raw materials, enhancing the nutritional elements in the product and producing multifunctional nutritional and health foods. Such as grain slimming powder, red bean barley Rice noodles, buckwheat powder, black sesame paste, etc.

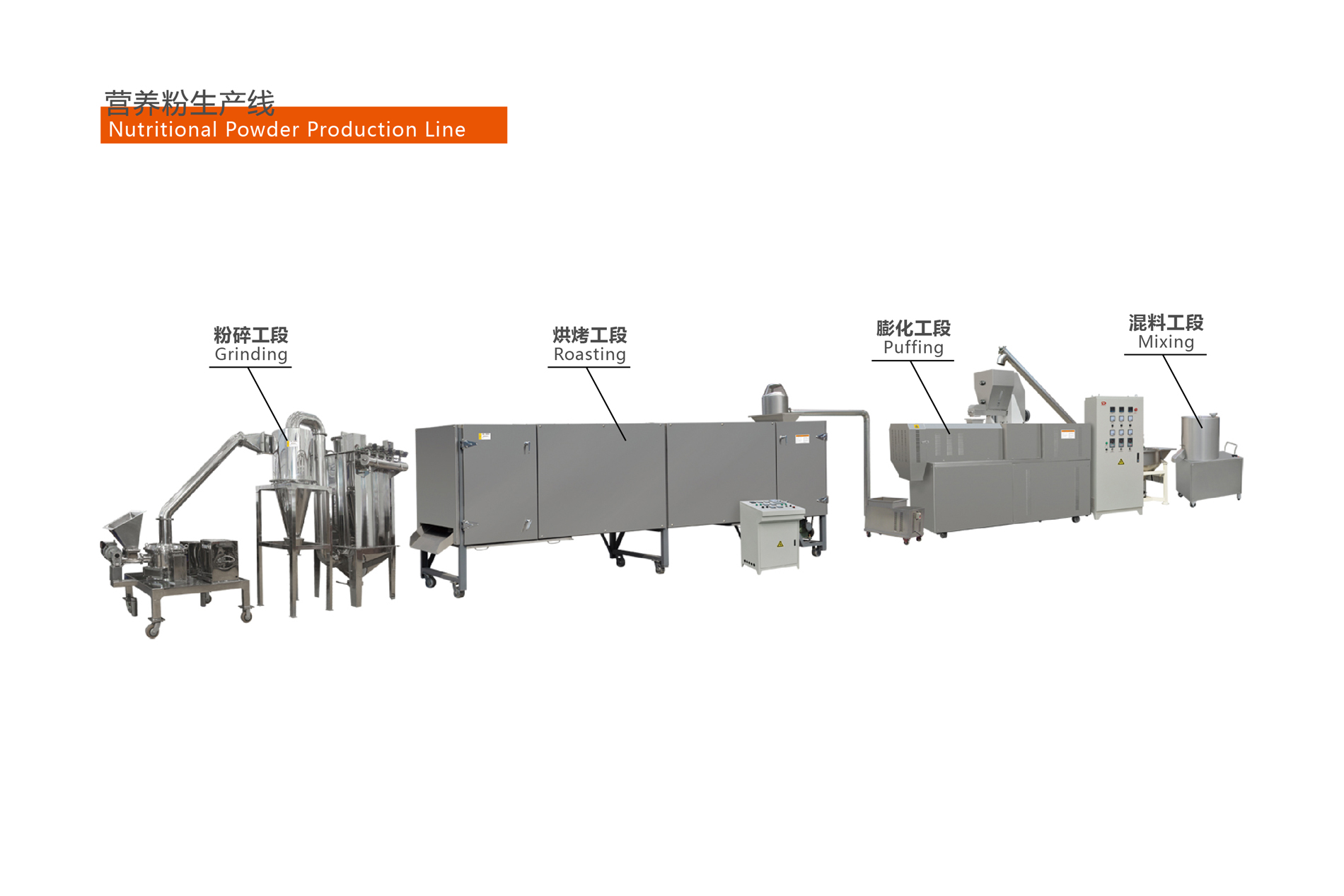

The following is an introduction to the production process of the nutritional powder production line:

1. Mixer: Mix the necessary raw materials for production thoroughly and evenly here.

2. Spiral feeder: The mixed raw materials are transported to the feeding hopper of the extruder, and the use of spiral rod feeding not only ensures uniform and stable feeding, but also prevents scattering. The rotating spiral rod can also perform secondary stirring on the raw materials during the feeding process, making the raw materials more evenly mixed.

3. Twin screw host: The mixed raw materials are extruded and expanded here, and the molecular structure of the raw materials is changed. After high-temperature and high-pressure production, they are finally extruded and formed by an extruder.

4. Air blower: Conveys the products produced by the extruder into an oven, and the height of the air blower can be freely determined based on the height of the oven.

5. Three layer electric oven: Bake the delivered product, drying its moisture to make it crispy and dry.

6. Ultramicro crusher: Crush the roasted product into different thicknesses according to production needs.

This nutritional powder production line has multiple host configurations, and each enterprise can choose the suitable production equipment according to factors such as production demand and factory area. The following are the two main configuration parameters of the extrusion and puffing machines for this production line:

| Model | Installed power | Power consumption | Capacity | Dimension |

| SLG65-CJ | 81.57kw | 53kw | 100-160kg/h | 16500*1150*2350mm |

| SLG70-A | 84.16kw | 55kw | 200-300kg/h | 17500*1150*2350mm |

Related Products

Related News

Submitted successfully

We will contact you as soon as possible