Introduction To The Nutritional Powder Production Line

1. Efficient production: The nutrient powder production line has the characteristics of high automation and continuity, which can achieve efficient production. By using modern production equipment and automated control systems, rapid and accurate production processes can be achieved. This efficient production can significantly increase production capacity and output, while reducing the demand for human resources.

2. Quality control: Nutritional powder is a food product that involves human health, therefore quality control is crucial. The nutritional powder production line adopts strict quality control standards and procedures, and ensures product consistency and high quality through automated monitoring and control systems. These systems can monitor key parameters such as temperature, humidity, pH value, etc., and automatically adjust them to ensure that the product meets specified standards and requirements.

3. Flexibility and Diversity: The nutritional powder market has a trend of diversification and rapid change, which needs to adapt to different product needs and market requirements. The nutritional powder production line can be flexibly adjusted and changed as needed to produce different types and specifications of products. This flexibility enables the production line to meet the needs of different customers and respond promptly to market changes to meet the diverse needs of consumers.

The nutritional powder production line developed by our company is another new extension of the twin screw extrusion technology. The traditional manual frying method is inefficient, hygienic, and difficult to control quality issues, resulting in a single processing material. The newly developed twin-screw extrusion technology makes up for the above shortcomings. It can process a wide range of raw materials, including Rice noodles, corn flour, soybean flour, buckwheat, oats, etc. At the same time, it can strengthen various nutrients and produce multifunctional nutritional and health food, such as Black sesame soup, red bean and barley Rice noodles, grain slimming powder, red jujube and lotus seed soup, buckwheat powder, etc., which are popular among people of all ages.

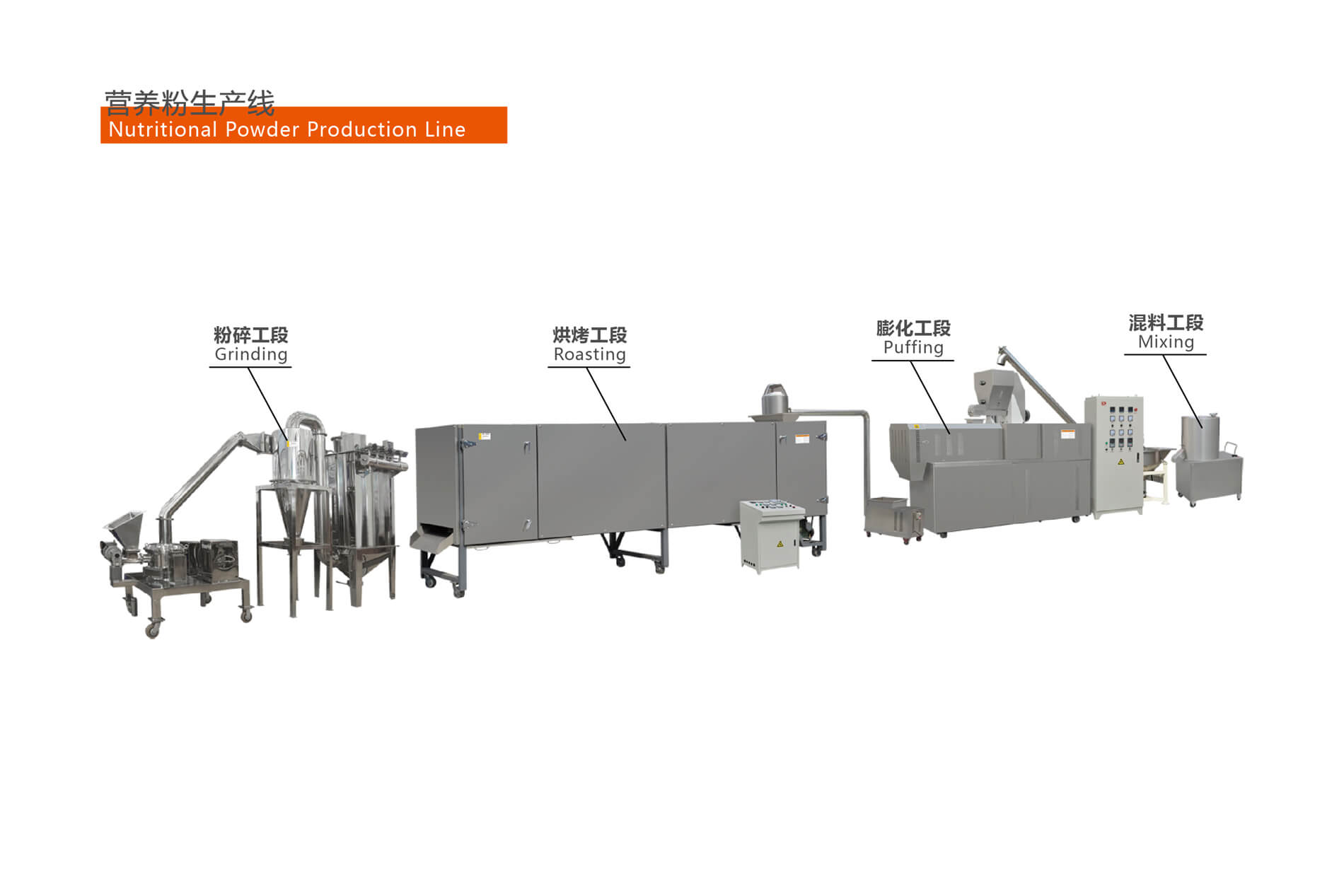

Process flow of nutritional powder production line:

1. Mixer: Mix and homogenize raw materials here to form standard production materials.

2. Spiral lifting machine: responsible for material transportation, using spiral feeding can ensure uniform and stable feeding, and it is not easy to spill.

3. Twin screw host: Extrude and expand the raw materials here. The twin screw extruder has good expansion effect and high output.

4. Air blower: responsible for conveying products to the oven, and the height of the air blower can be determined based on the height of the oven.

5. Three layer electric oven: Bake the product to reduce internal moisture and facilitate subsequent production work.

6. Ultramicro crusher: Crush the roasted product into fine powder.

Technical parameters of nutrient powder production line:

| Model | Installed Power | Power Consumption | Capacity | Dimension |

| SLG65-CJ | 81.57kw | 53kw | 100-160kg/h | 16500*1150*2350mm |

| SLG70-A | 84.16kw | 55kw | 200-300kg/h | 17500*1150*2350mm |

Related Products

Related News

Submitted successfully

We will contact you as soon as possible