Introduction To High Yield And Fully Automatic Pet Food Production Line

Productivity: Continuous, automatic process start and stop, fast and easy conversion, and efficiency for easy cleaning and maintenance.

Flexibility: Supports product innovation, with multiple choices of raw materials, sizes, shapes, and fillers for processing (with optional co extrusion attachments), thereby expanding the product range.

Cost effective: Strengthening the high-temperature short-term conversion process, saving raw materials, energy, and water; Easy to maintain, hygienic and compact design, requiring a small footprint.

Expert System: Specially designed by our engineers with advanced automation functions, it ensures precise process control to achieve easily replicable and consistent product quality.

The pet food production line developed by our company endows pet food with novel forms, unique flavors, and colors. And it adapts to the needs of the modern pet food market with the most scientific nutritional ratio and easy digestion characteristics. Taking extruded dog chew glue as an example, it undergoes scientific mixing of various materials, is extruded in an extrusion machine, and finally extruded into different shapes such as stick and bone chew pet food. It can provide essential nutrients for canine animals, such as protein, fat, vitamins, etc., as well as provide teeth grinding for dogs of different ages to satisfy their chewing habits. At the same time, it can also strengthen gums and jawbones, clean the oral cavity, remove tartar, and reduce disease transmission.

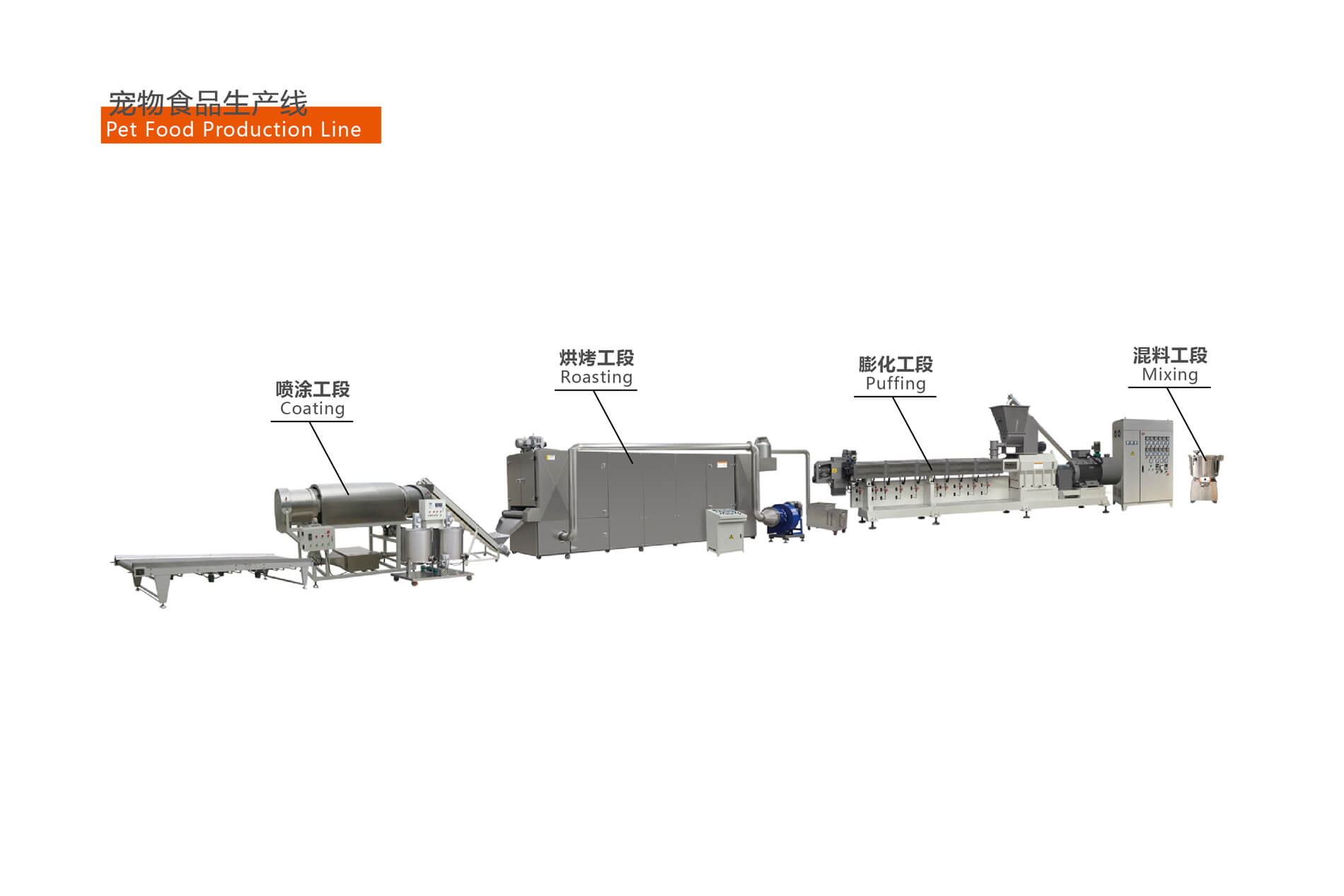

Introduction to the process flow of pet food production line:

1. Mixer: Configure the necessary raw materials for production here. Mix the raw materials with a certain amount of water and other nutrients to form the production raw materials.

2. Spiral feeding machine: Conveys the configured raw materials to the next equipment, and the spiral feeding is not easy to spill, ensuring uniform and stable feeding.

3. Twin screw host: Squeeze and puff the incoming raw materials, resulting in a crispy taste of the puffed product.

4. Air blower: Conveys the products produced by the extruder into an oven, and the height of the air blower can be freely adjusted according to the height of the oven.

5. Five layer fuel oven: Dries the product to moisture, making it crispy and easy to store.

6. Large elevator: Transport the product to the next device.

7. Spraying line: Seasoning the baked product, and the flavor of the seasoning can be determined according to production needs.

8. Cooling conveyor: Cool the product and transport it for packaging.

Advantages of pet food production line products:(Taking dog food as an example)

1. Improve the palatability of dog food. Dry dog food, after being puffed, becomes crispy, and pet dogs have a good taste and cleaning effect on their oral teeth during biting and swallowing;

2. To change and improve the nutritional value of dog food, many nutrients need to be aged and expanded to become nutritious. Otherwise, not only will it not bring effective nutrition to the pet dog, but it will also cause discomfort such as diarrhea and vomiting;

3. Improve the digestion and absorption rate of dog food for pet dogs, and the puffed dog food can be absorbed more comprehensively and comprehensively by pet dogs. Currently, there is even a "double puffing" process, which aims to enable pet dogs to better absorb all the nutrients in dog food;

4. Through the process of puffing and granulation, the shape and structure of dog food have been changed, making it easier for pet dogs to eat and eat more dog food;

5. Changing the different nutritional indicators of dog food, such as reducing water content, can increase the shelf life of dog food, making it more convenient for pet owners to store and feed anytime, anywhere, both safe and convenient;

6. Changing the density of dog food, squeezing granulation, and puffing can also increase the bulk density of dog food, making it easier to purchase and transport;

Related Products

Related News

Submitted successfully

We will contact you as soon as possible