FLS Snack Products Cooling Conveyor Machine

FLS Snack Products Cooling Conveyor Machine is a supporting equipment for the oven, which is used to cool and transport baked materials. This machine adopts stainless steel mesh belt driven by chain to transport materials. The machine is reasonable in design and easy to operate.

Introduction to FLS Snack Products Cooling Conveyor Machine:

FLS Snack Products Cooling Conveyor Machine is a supporting equipment for the oven, which is used to cool and transport baked materials. This machine adopts stainless steel mesh belt driven by chain to transport materials. The machine is reasonable in design and easy to operate.

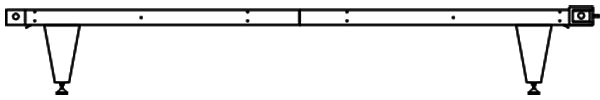

Structure Diagram of FLS Snack Products Cooling Conveyor Machine:

FLS Snack Products Cooling Conveyor Machine Technical Parameters:

Power: 0.55KW

Effective length of mesh belt: (can be customized according to customer requirements)

Overall dimensions: (according to customer requirements) ×900 × 700㎜

FLS Snack Products Cooling Conveyor Machine Installation and Operation:

1. According to the position of the production line and the oven, place the equipment on a flat and solid ground, and place the distance between the machine and the oven.

2. Adjust the height of the anchor to make the equipment stable, so as to prevent uneven stress on all parts of the machine body from affecting the normal operation of the equipment.

3. The power supply shall be equipped with knife switch, and the equipment shall have reliable grounding protection. Check whether the electrical components are damaged or loose. Before starting the machine, check whether the connectors are connected reliably and whether the electrical wiring is connected falsely.

4. Connect the power supply and operate the machine with no load. Observe whether the machine is abnormal during operation.

5. If everything is normal, it can be put into formal production.

FLS Snack Products Cooling Conveyor Machine Maintenance:

1. Regularly check whether the fixing bolts of each connecting flange, bearing seat and transmission system are loose, and tighten them if any.

2. Clean the conveyor belt when it is not in use.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible