Fully Automatic Soy Protein Production Line

1. Soybean protein can replace isolated protein and be added to meat products, which not only increases the protein content of meat products, but also absorbs excess fat, making it less greasy and more fleshy, achieving the goal of economy and affordability.

2. Soy protein does not contain cholesterol, and people with cardiovascular disease can consume it with confidence.

3. Soybean protein is an ideal plant protein that contains eight essential nutrients for the human body.

4. The puffed soybean protein, due to rapid decompression and explosion at the outlet, can remove the unpleasant odor in the soybean and reduce the gas production of soybean protein after consumption.

The products produced by the soy protein production line are mainly made from low-temperature soybean meal, soy protein isolate, gluten powder, and other raw materials. The process of mixing and homogenizing materials, steaming and ripening, high-temperature sterilization, and extrusion molding is completed in a twin-screw extruder to produce high-strength and high toughness soy protein food with a layered muscle fiber structure, similar to the taste and texture of meat. According to the different extrusion molds and auxiliary equipment, cylindrical, block, sheet, granular and other shapes can be produced. This type of brushed protein food has good water absorption and oil retention properties, strong flavor adaptability, and high-temperature stewing resistance. Therefore, it can be widely used in meat products, fast food, frozen food, filling, instant noodle seasoning, etc. It can also be made into different flavors of vegetarian meat snacks and vegetarian dishes.

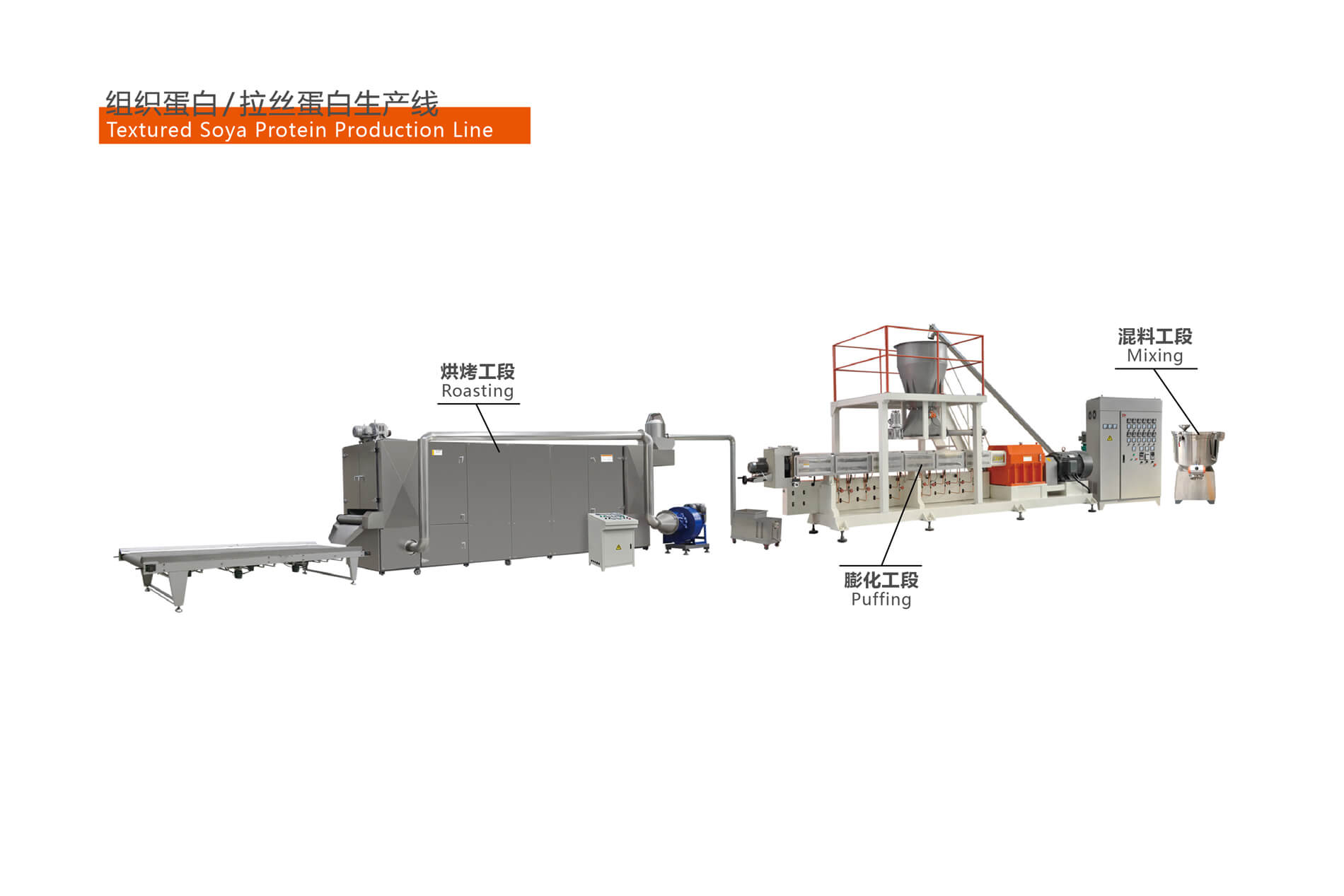

Introduction to the process flow of soy protein production line:

1. Mixer: Mix the raw materials required for production with a certain amount of water thoroughly and evenly.

2. Spiral feeding machine: The mixed raw materials are transported to the feeding hopper of the extruder, and the screw rod is used for feeding, which is more uniform, stable, and not easy to spill. The screw rod also has a secondary stirring effect on the raw materials.

3. Twin screw host: The mixed raw materials are processed through a high-temperature and high-pressure environment to change the internal molecular structure of the product. After expansion, they are extruded into shape by an extruder.

4. Air blower: Conveys the produced product to the next equipment, and the height of the air blower can be freely determined based on the height of the oven.

5. Five layer oven: Dry the transported products to reduce internal moisture and facilitate storage.

6. Cooling conveyor: Cool the product and transport it for packaging.

The plant tissue protein produced by this soy protein production line has a good granular structure. After soaking, it can be made into various flavors of vegetarian food. In the process of processing tissue protein, different flavor seasoning agents can be added, and then added to convenient food and snack food, and different flavors of food can be made. Our company has a variety of production equipment configurations, and enterprises can customize their production equipment according to the size of the factory and the demand for output.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible