Spiral Papad Fryum Manufacturing Equipment

The 2D 3D Granular Food Production Line Uses Potato Starch And Corn Starch As The Main Raw Materials To Produce A Variety Of Secondary Extruded Foods Of Different Shapes, Such As Pea-Shaped And Screw Shape, Square Tube Shape, Round Tube Shape, Wave Shape, Etc., The Food Produced By It Is Very Popular In The Market. The Production Line Is Characterized By Reasonable Mechanical Configuration, High Degree Of Automation, Stable Performance And Convenient Maintenance. The Production Line Is Completed In One Step From Raw Materials To Finished Products, And The Products Produced Are Crispy And Delicious After Being Fried.

This process line uses potato starch, corn starch as main materials to produce a variety of twice extrusion food in different shapes which are popular in the market, such as crispy pea, shell, screw, square tube, round tube, wave, etc. This process line is characterized by unique technics, rational configuration, high automation and stable performance. It can finish steaming, extruding and shaping in one step without a boiler. The products have similar shapes to the real one and taste crispy and delicious after fried.

Technical Parameter

Model | Installed power | Power consumption | Capacity | Dimension |

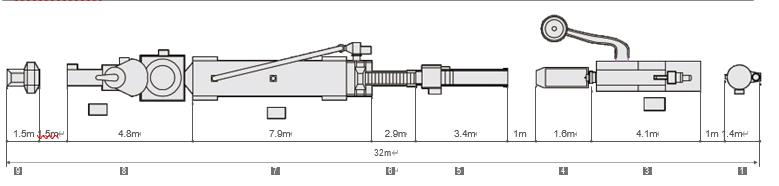

DLG90 2D Pellet process line | 53.32kw | 37kw | 60~85kg/h | 32000×2400×2900mm |

DLG130 2D Pellet process line | 81.15kw | 57kw | 110~140kg/h | 32500×2400×2900mm |

Production Display

Schematic Diagram of Production Line

Related Products

Related News

Submitted successfully

We will contact you as soon as possible