Introduction To Fully Automatic High Yield Nutritional Rice Production Line

1. Save resources and improve efficiency

2. Improve people's dietary nutrition, supplement missing micronutrients, and meet the normal physiological needs of the human body

3. Reduce the occurrence of various nutritional deficiencies

The fully automatic nutritional rice production line is developed to address the significant loss of nutrients in rice during traditional rice milling production processes. Rice and other nutrients can be made into high value-added products through extrusion technology. During this process, broken rice and rice bran can be reused. The entire production process is simple and easy to operate. After crushing the broken rice, it is mixed with a certain amount of water, oil, etc. At a certain temperature, the raw materials are matured in the extruder, and then extruded by a mold to form a rice shape. The reconstructed rice grains are then dried at low temperature. This squeezing technique effectively avoids the loss of nutrients, making it a nutrient rich fortified rice.

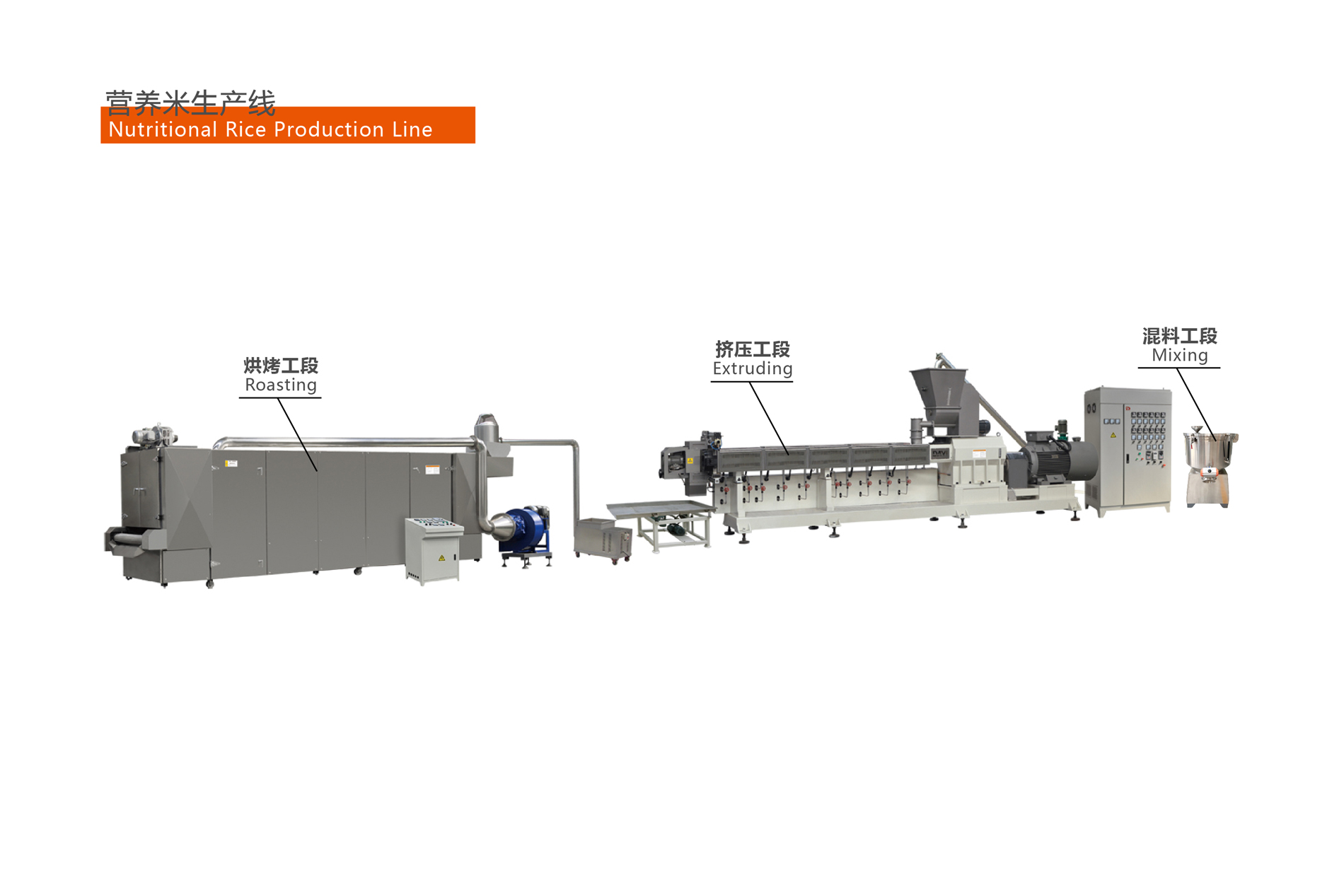

Process flow of nutritional rice production line:

1. Powder mixer: mix the working raw materials required for production evenly here. This production line mainly uses Rice noodles as the main raw material, and can selectively fill a variety of vitamins and minerals as required.

2. Spiral feeder: The mixed raw materials are transported to the feeding hopper of the extruder, and the use of spiral rods for feeding can ensure uniform and stable feeding without easy scattering. The spiral rods also serve as a secondary mixer for the raw materials.

3. Twin screw host: The mixed raw materials are extruded and expanded in an extrusion machine, which undergoes high-temperature and high-pressure extrusion and ultimately extrudes the shape of rice particles through the extruder.

4. Cooling vibration machine: The product produced by the extruder is vibrated to avoid adhesion, while being cooled and transported to the next equipment.

5. Air blower: The cooled product is transported to the oven, and the height of the air blower can be freely determined based on the height of the oven.

6. Five layer electric oven: It dries the incoming products to reduce their internal moisture and keep them dry for easy storage. Our company has multiple capacity configurations of ovens, and customers can customize and choose the appropriate oven according to their production needs.

The product produced by the nutritional rice production line is very popular among consumers in developed countries such as the United States and Japan. Artificial nutritious rice, also known as instant rice, is increasingly favored by consumers as the pace of society accelerates. The following is an introduction to several host parameters of the production line. Customers can choose the equipment that suits them according to their own production needs and factory area.

| Model | Installed power | Power consumption | Capacity | Dimension |

| SLG65-CJ | 53.52kw | 34.8kw | 100-150kg/h | 16200*1200*2200mm |

| SLG75-A | 127.24kw | 82.7kw | 200-300kg/h | 19780*2100*2300mm |

| SLG72-E | 489.77kw | 342.84kw | 700-900kg/h | 59900*9000*7000mm |

Related Products

Related News

Submitted successfully

We will contact you as soon as possible