Pet Dog Cat Bird Food Extruder Processing Machine

The Automatic Pet Food Production Line Uses Flour, Corn Meal, Soybean Meal, Meat Meal, Fish Meal, Bone Meal, Etc. As Raw Materials, And Uses An Automatic Mixing System To Realize Automatic Scientific Proportioning And Mixing. The Twin-Screw Extruder Extrudes Various Shapes And Then Bakes Dry And Spray Can Produce Various Shapes, Balanced Nutrition, And Good Palatability Formula Pet Food; Twin Screw Extrusion Technology Produces Pet Food, Which Can Keep The Nutrients In The Formula Raw Materials Intact, Easy To Digest And Absorb, And The Formula Shape Is Easy Change; Optimization Of The Entire Assembly Line Configuration, High Degree Of Automation, Precise Control Of The Production Process, Stable Product Quality, High Production Efficiency, Sanitation And Environmental Protection; Provide A Variety Of Configurations And Output, Which Can Produce Dog Food/Cat Food/Bird Food/Fish Food/ The Production Line Of Aquatic Feed Is For You To Choose!

Pet food pellet making machine endues doggy food with the amount of vitamins, digestible shape, novel shape, and particular taste to meet with the dreams of modern-day market. the canine chewing food is extruded into a variety of shapes together with stick, bone, and so forth. this form of meals not handiest can offer nutrients to puppies, like protein, fat, eating regimen, and so on, but additionally fulfill the dog nature interest, gain to its robust teeth, cleanness of mouth and teeth, and forestalls ailment.

Technical Parameter

Model | Installed power | Power consumption | Capacity | Dimension |

SLG65-CJ Pet food process line | 62.79kw | 41kw | 100~150kg/h | 25500×1200×2000mm |

SLG75-A Pet food process line | 136.74kw | 89kw | 200~350kg/h | 26600×2100×3070mm |

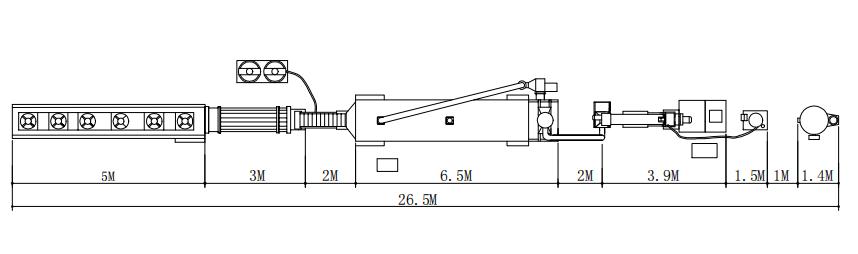

Schematic diagram of production line

Production Display

Related Products

Related News

Submitted successfully

We will contact you as soon as possible