Corn Chips Machine

This Puff Snack Making Machine Can Use Corn, Rice, And Other Grain Powder As Raw Materials To Produce Directly Puffed Snacks In Variou Shapes, Such As Chip, Ball, Ring, Stick, Flake, Flower, Etc. After Dried And Flavroed, The Snacks Are Crispy And Tasty Which Are Very Popular In The Market. This Puff Snack Machine Is Characteristics Of Simple Opeation, Reasonable Structure, Low Consumption, And High Efficiency, Which Make It The Best Choice For Medium Factory.

This Fried cheetos kurkure niknak processing line can use corn grits instead of the powder material to produce the irregular stick sanack. This extruder is specially designed with one screw only for such cheetos, kurkure, or niknak. After shaped from extruder, the products will be sent into the rotary sifter to take down extra grits sticky on the surface. The waste grits can be collected and used again as raw materials. So this processing line can lower down the production cost. After fried and flavored, the final cheetos or kurkure will be more tasty and crispy.

Technical Parameter

Model | Installed power | Power consumption | Capacity | Dimension |

SLG65-C Puff snack process line | 63.41kw | 41kw | 100~150kg/h | 18000×1200×2000mm |

SLG70-A Puff snack process line | 86.06kw | 56kw | 250~300kg/h | 23000×2000×3000mm |

SLG85-A Puff snack process line | 131.06kw | 98kw | 350~400kg/h | 31000×2000×3000mm |

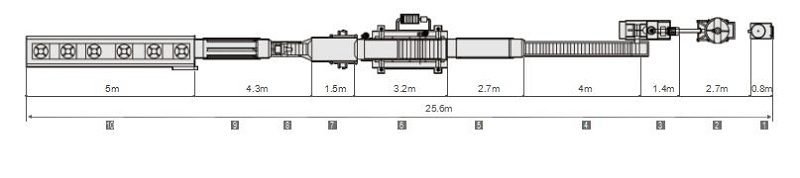

Schematic diagram of production line

Production Display

Related Products

Related News

Submitted successfully

We will contact you as soon as possible